Flexible design with façade panels

High-quality solution for impressive façades

Aluminium façade panels are one of the classics for metal building envelopes. The high-quality metal panels are not only an extremely economical solution for commercial and industrial construction, thanks to flexible design options they are also convincing in residential construction. With the façade panels from BEMO, you also use systems with a high recycled content in the material used and the option of returning the material to the recycling process at the end of its long service life.

A special highlight in façade design is BEMO-UNIKO panels with free profile geometry, which are produced individually tailored to the respective project and design of a building.

-

Efficient and economical façade solutions

with BEMO panel facades -

Great design variety with variable installation direction

and individual colour and material selection -

Sustainable systems

thanks to the high recycling content of the material used -

Fastening panels made easy

with the BEMO-PRIMO clip facade

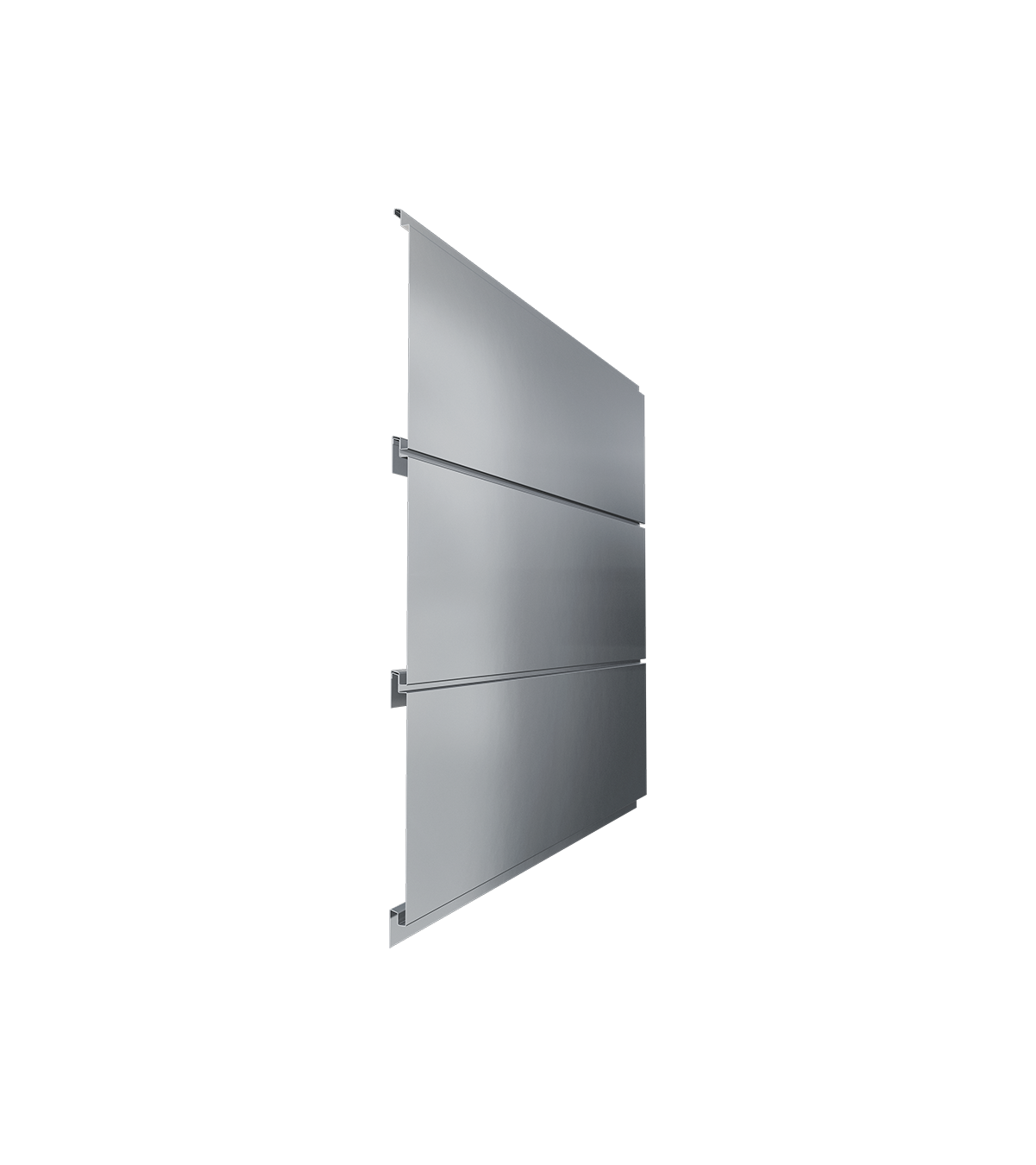

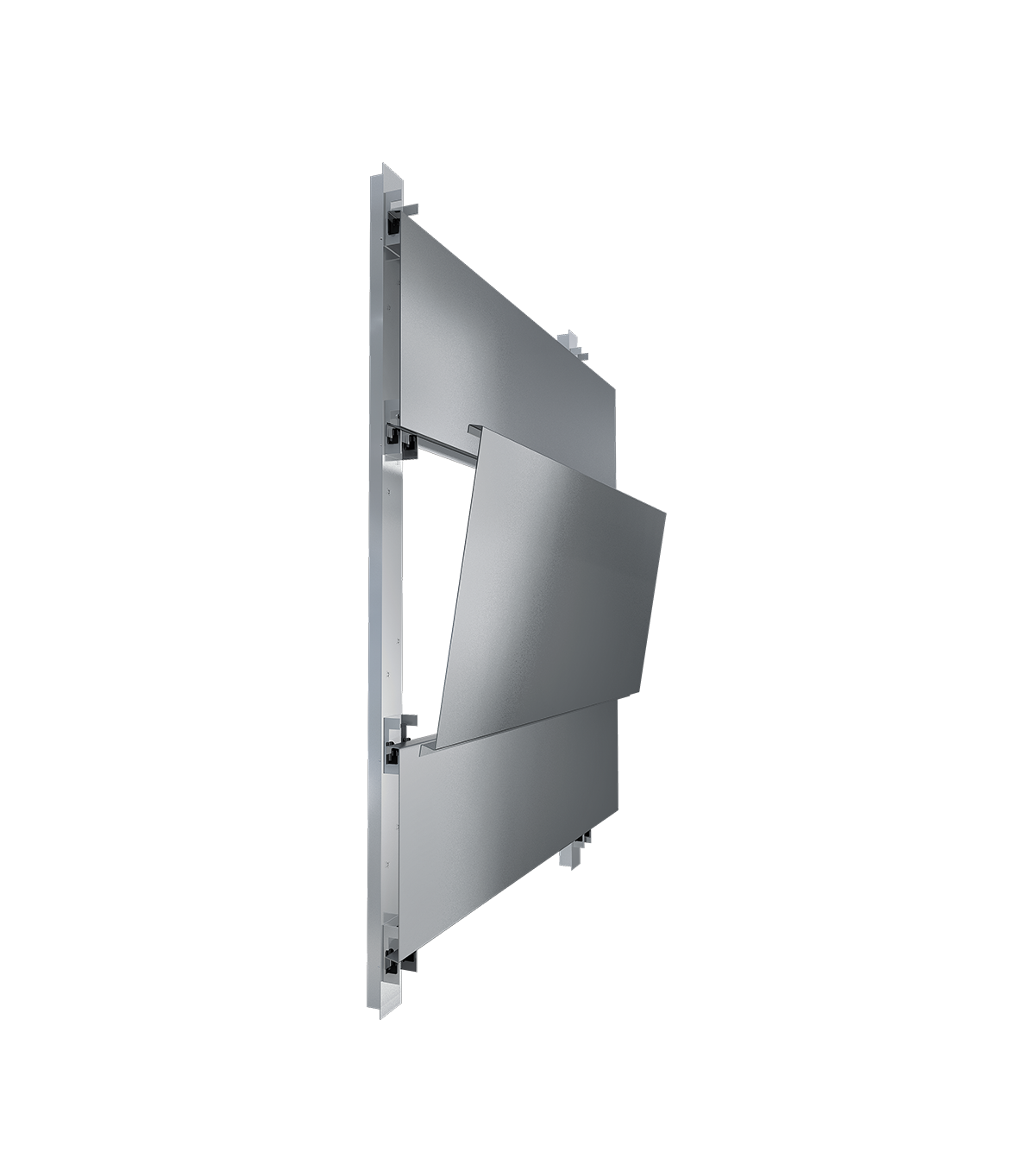

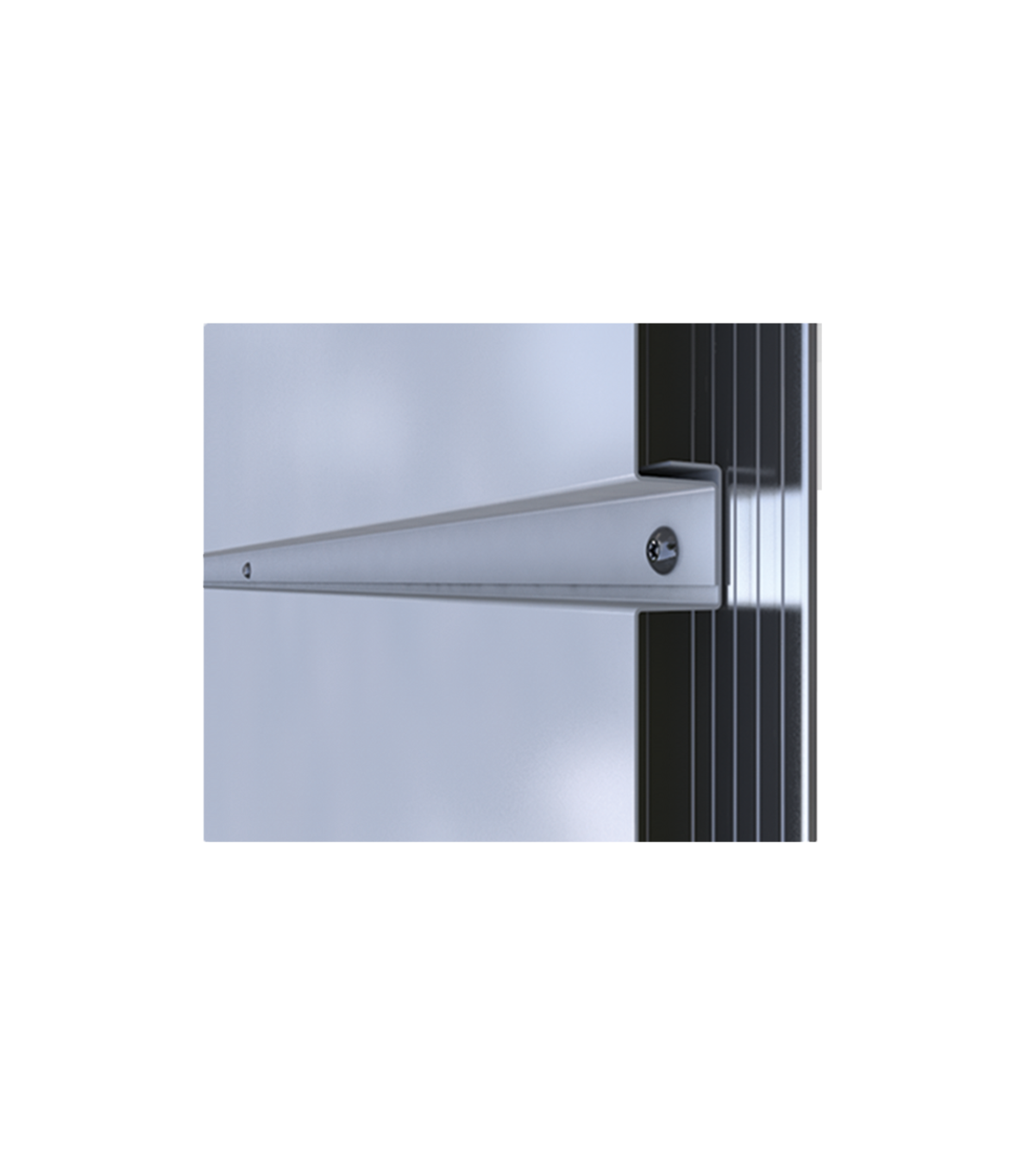

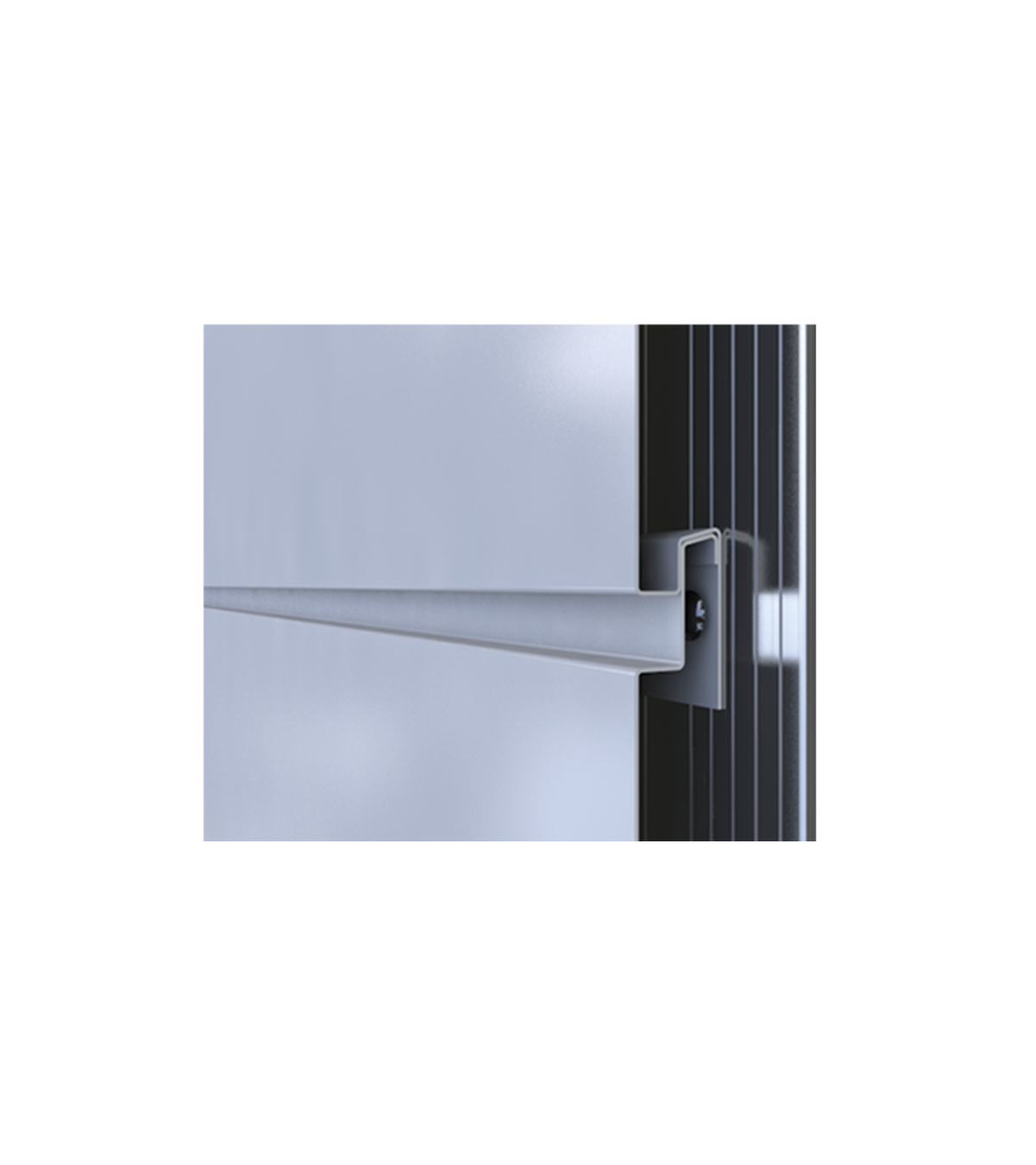

Fastening façade panels using clip method

The efficient and economical façade solution BEMO-PRIMO

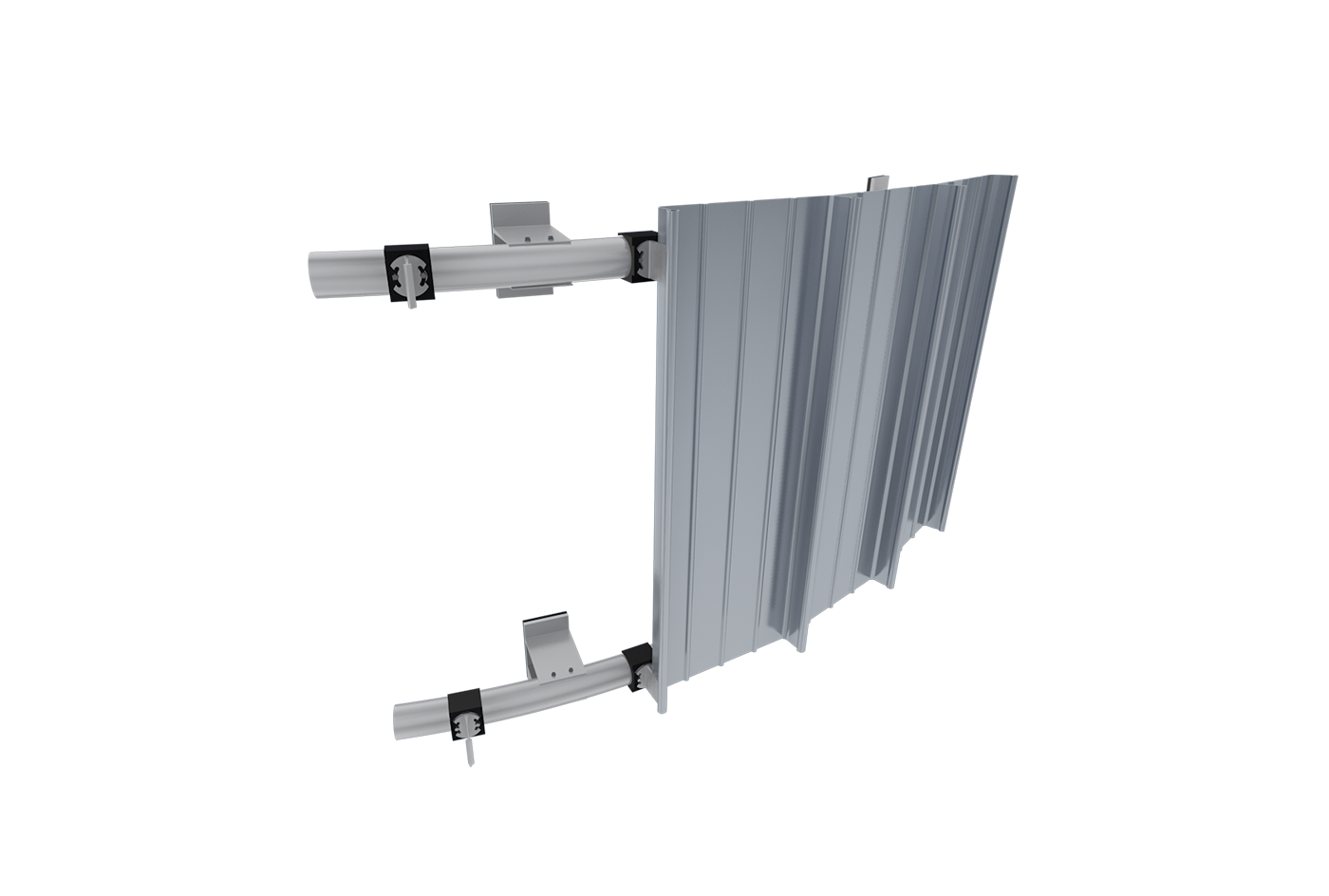

A PRIMO steel clip façade is the economically optimal façade solution for your company building. Fixing panels cannot be easier: The panel installation is highly efficient with the clip façade from BEMO. Grid dimensions can be freely designed between 200 mm and 800 mm – even multiple grid dimensions on the same project. The PRIMO substructure can be mounted on any substrate or substructure. These can be concrete, timber, cassettes or mixed substrates.

Panels fastening made easy: PRIMO clip façade for easy installation

Final assembly of the panels uses the clip method which is fast and economical. Corner and reveal formations complete the high-quality overall appearance of the PRIMO clip façade. Panel widths and lengths can be freely selected. PRIMO rails vary in depth. This allows connections to façade penetrations to be made precisely and the panels to be fixed quickly.

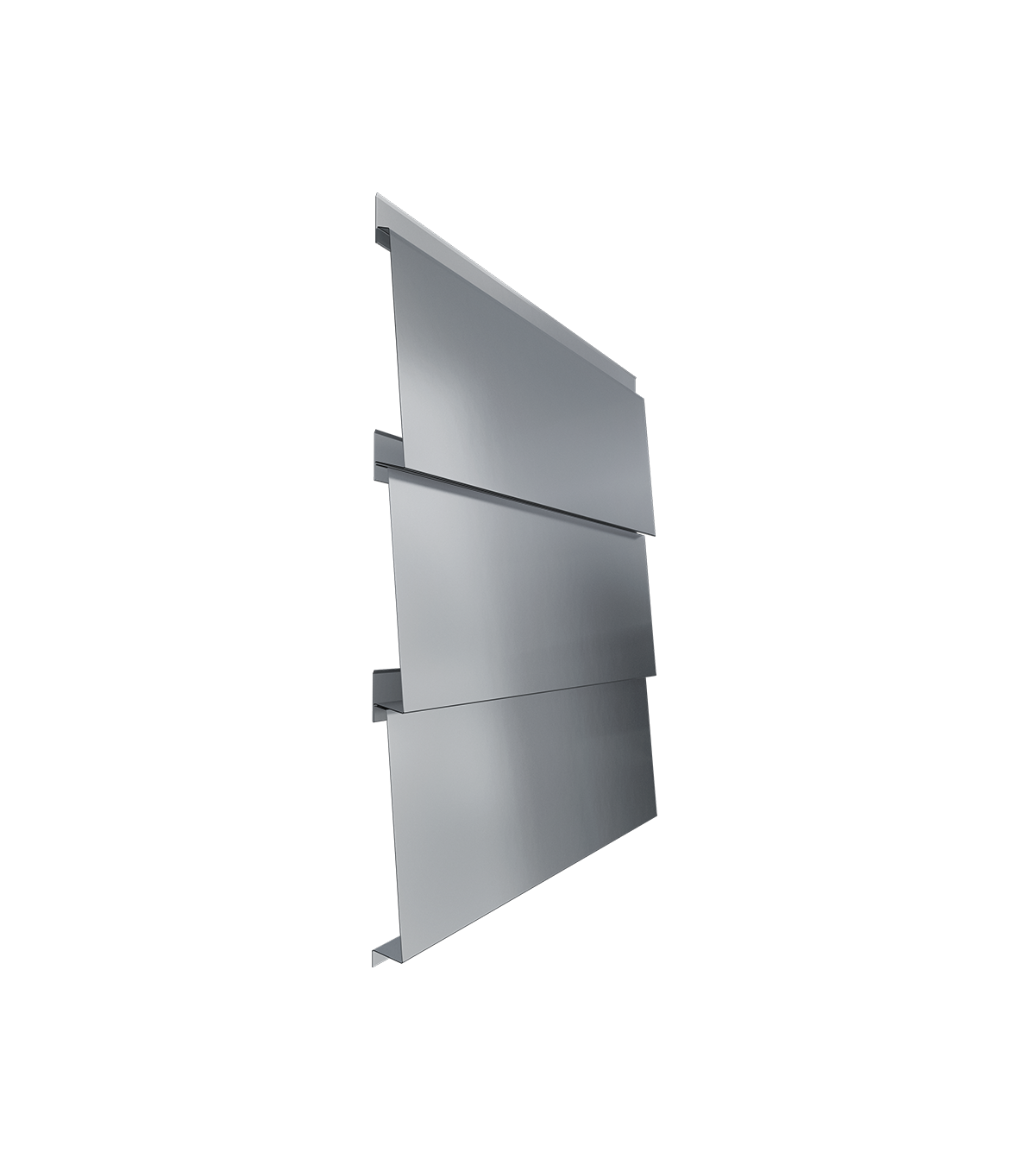

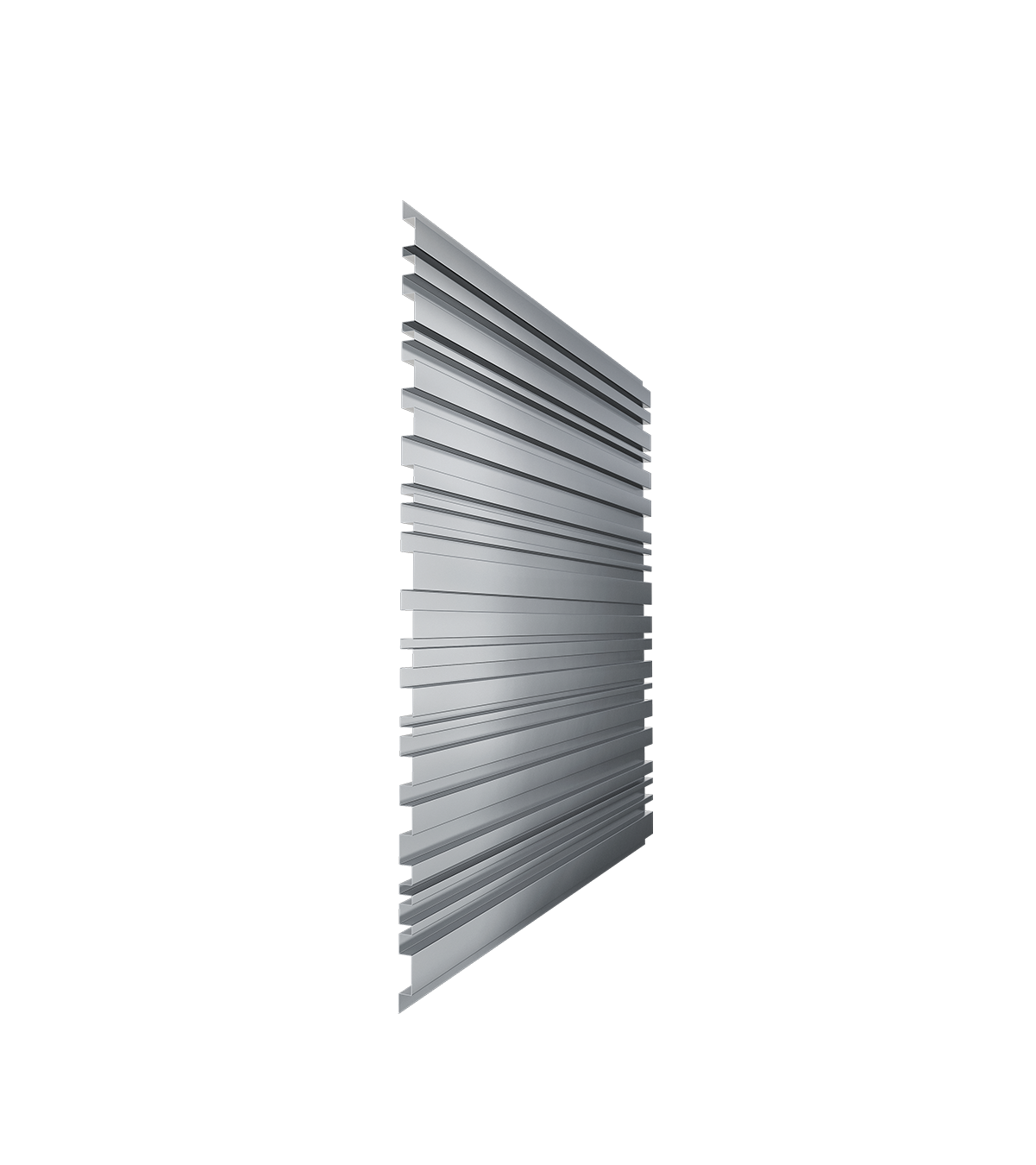

BEMO façade panels (sidings)

Individual and freely designable - almost limitless

BEMO metal façade panels for individual and free designs, horizontal, vertical, or diagonal. The façade fastening is concealed, depending on the requirements and application. The façade fastening is visible or free sliding for hanging. BEMO has the right solution for every requirement. The surfaces and colours can be freely selected and designed.

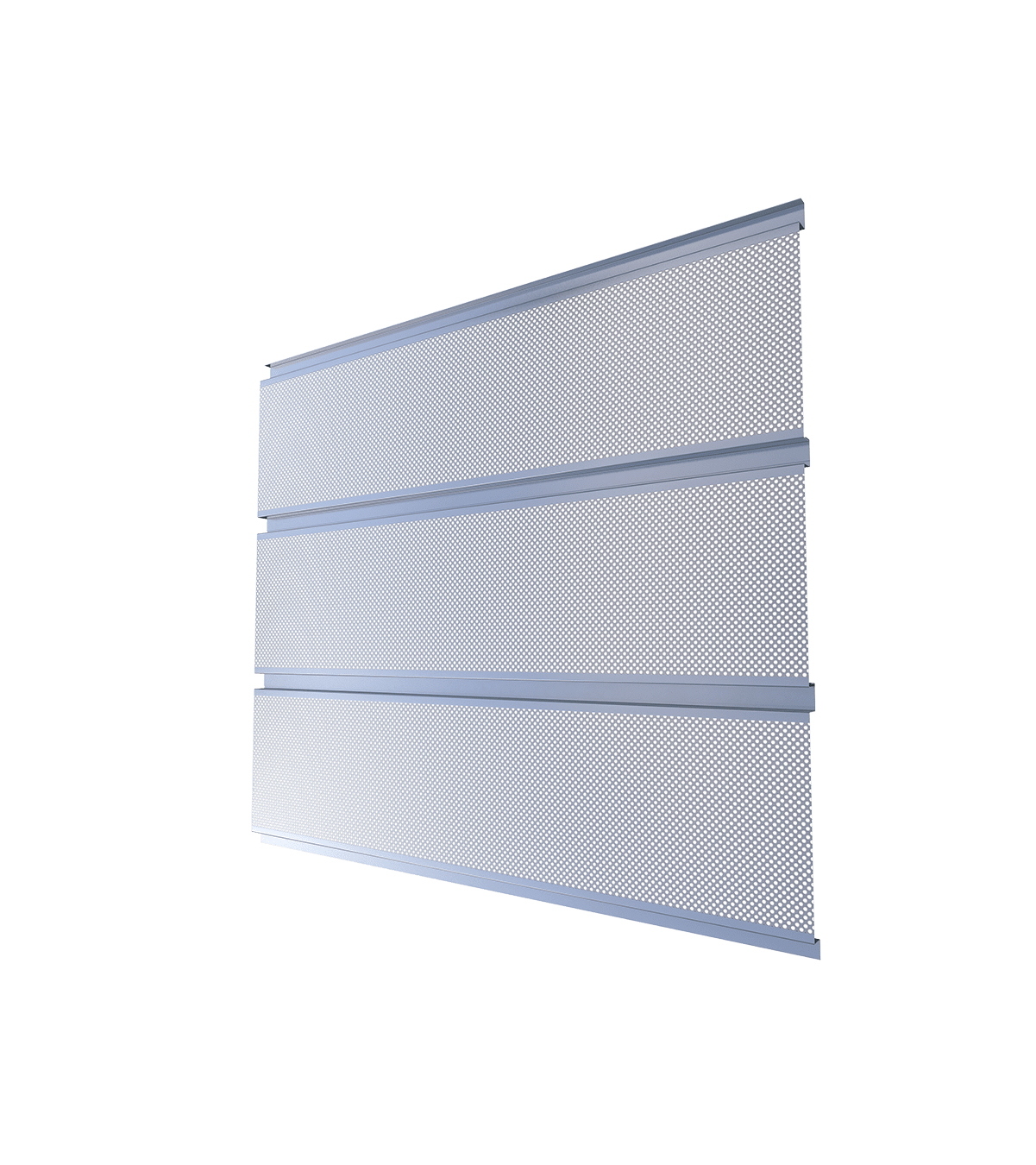

BEMO façade panels are available in several metal variants and a wide variety of colours and surfaces, including perforated designs.

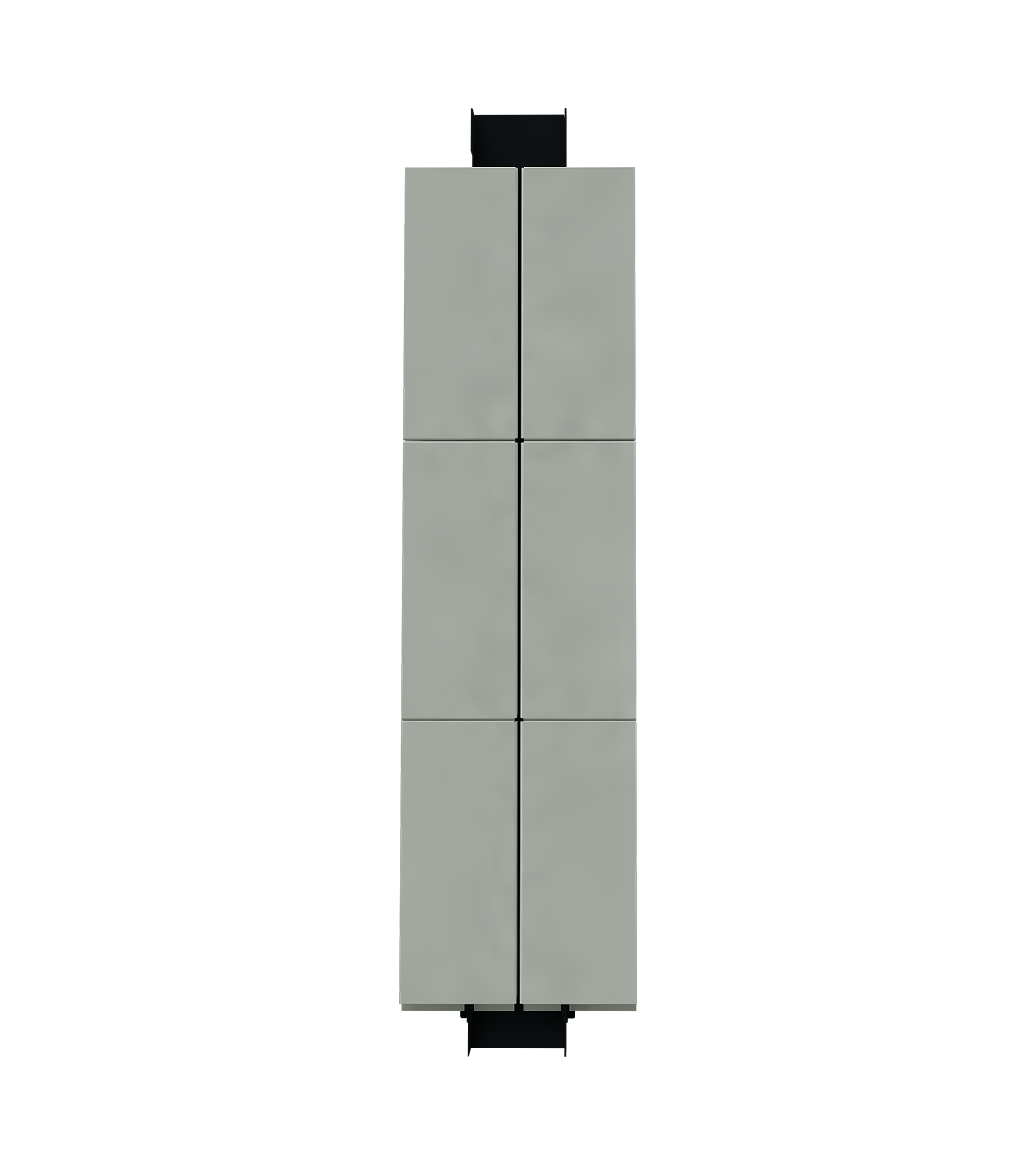

Box Panel

Plug-in Panel

Inverted Panel

BEMO-UNIKO

BEMO-PRIMO

visible fastening

concealed fastening

Panels perforated

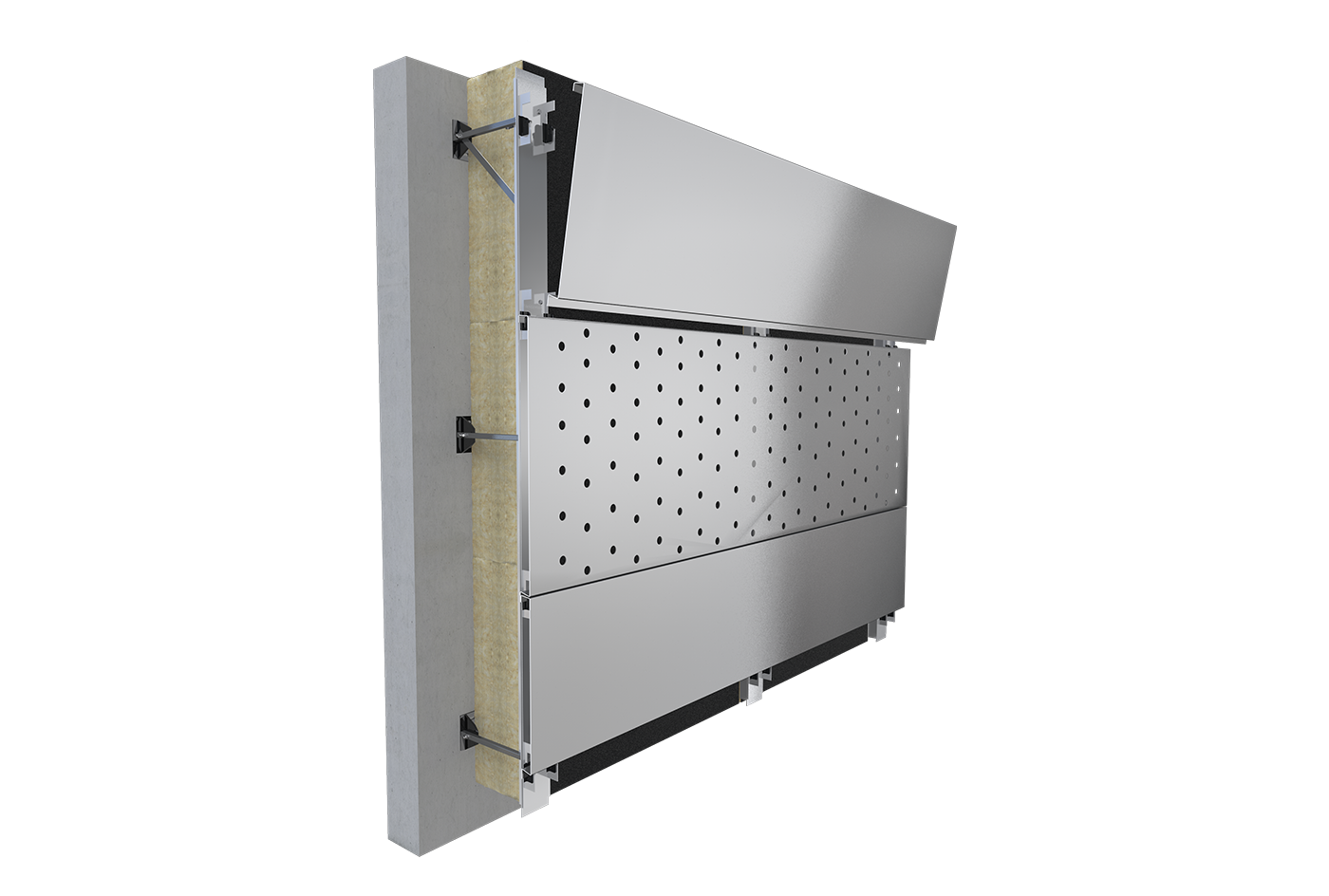

Façade system with façade panels and matching substructure

Compensation of tolerances – avoidance of thermal bridges

The substructure serves as a link between the façade cladding and the load-bearing wall. By being anchored in the outer wall, it transfers the weight of the façade cladding and the façade panels to the structure of the building. With the innovative substructure systems from BEMO, tolerances can be compensated and thermal bridges in the wall can be avoided. In close cooperation with you, we work out which substructure suits your individual façade cladding, taking all the circumstances into account.

Inspiration

Eislingen gym

Emser Thermenhotel

New construction of police and fire station

Double-deck three-field sports hall FFM

Petrol station Dorfen

360° Service

Broad technical support

BEMO has its own design office with system-experienced technicians and engineers, all equipped with the latest 3D design technology, some of it developed in-house. From the initial consultation on the implementation of the desired design, the choice of materials and the shaping, the first technical details and static preliminary measurements to the complete implementation and workshop planning.

Cost estimates, technical optimisations or even variant calculations help you to optimise your project economically. 3D measurements as the basis for our well thought-out and assembly-friendly systems and implementation in 3D design. This is what we mean by comprehensive partnership with BEMO.