Rainscreen systems from BEMO for all requirements of rainscreen façades

Structurally safe with maximum protection against moisture damage

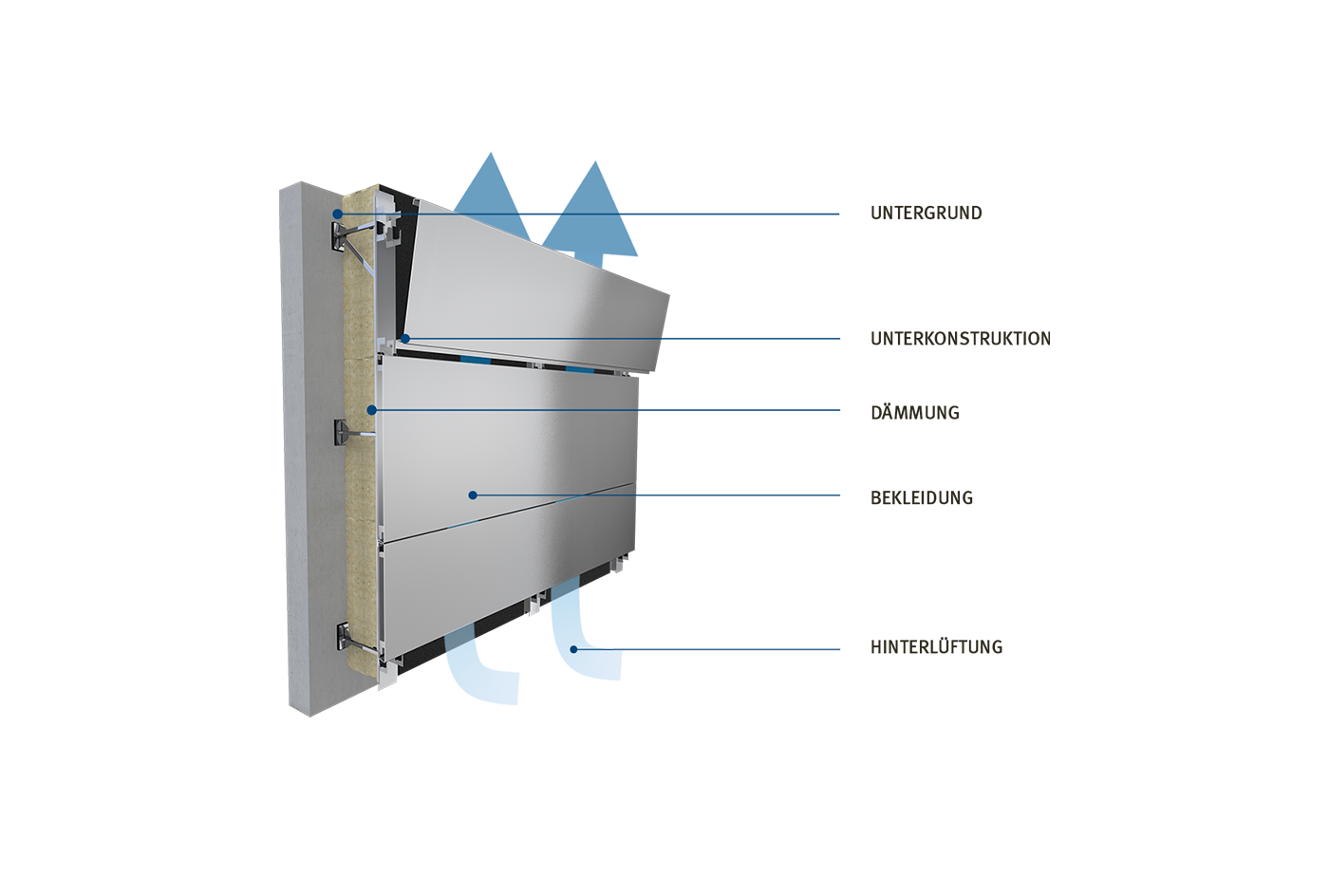

Systems are the interaction of several components that are perfectly designed and coordinated with each other. The interaction of matching components ensures safety and traceability, thoroughly tested and documented performance criteria. A rainscreen system (= rear-ventilated façade) is such a system for rainscreen façades: optimal in terms of structure, statically safe, optically flexible to design and adaptable to almost all requirements.

Compliance with the most modern fire protection requirements and the highest level of moisture protection are guaranteed with the rear ventilated façade system. The rear ventilation level of the rainscreen system enables the moisture that diffuses through the component to be regularly removed, thus preventing moisture damage to the structure of the rainscreen façade.

The anchoring base of the rainscreen system (concrete, masonry, timber, etc.) can be different. There are virtually no limits to the design possibilities with the BEMO variety of cladding products.

-

Meet the highest fire protection requirements

also for storey construction -

Passive house level is possible due to

TEKOFIX-A++ bracket without thermal bridging -

Optimal building physics and

statically safe façade system -

Endless design possibilities

thanks to BEMO product diversity in the façade sector

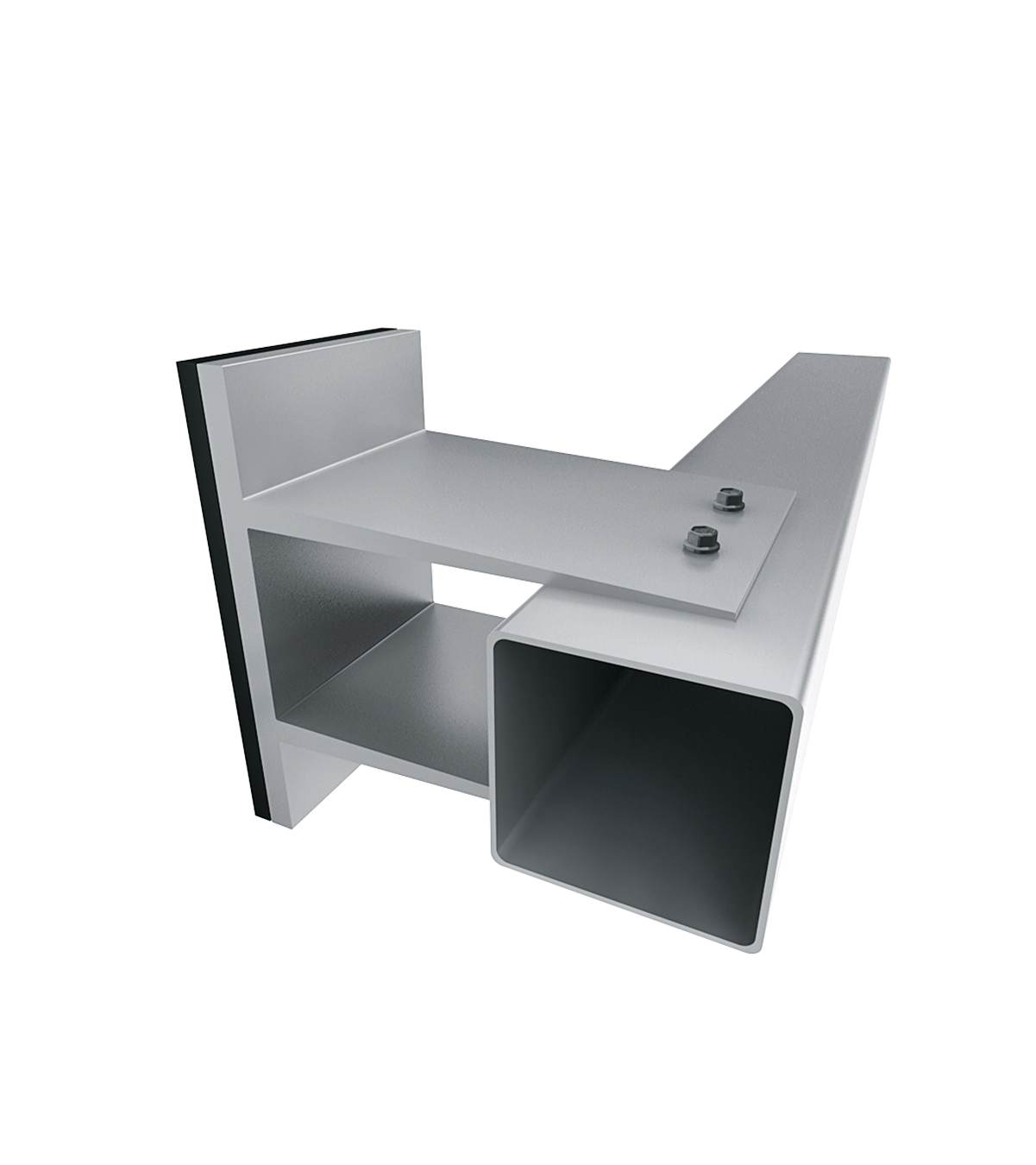

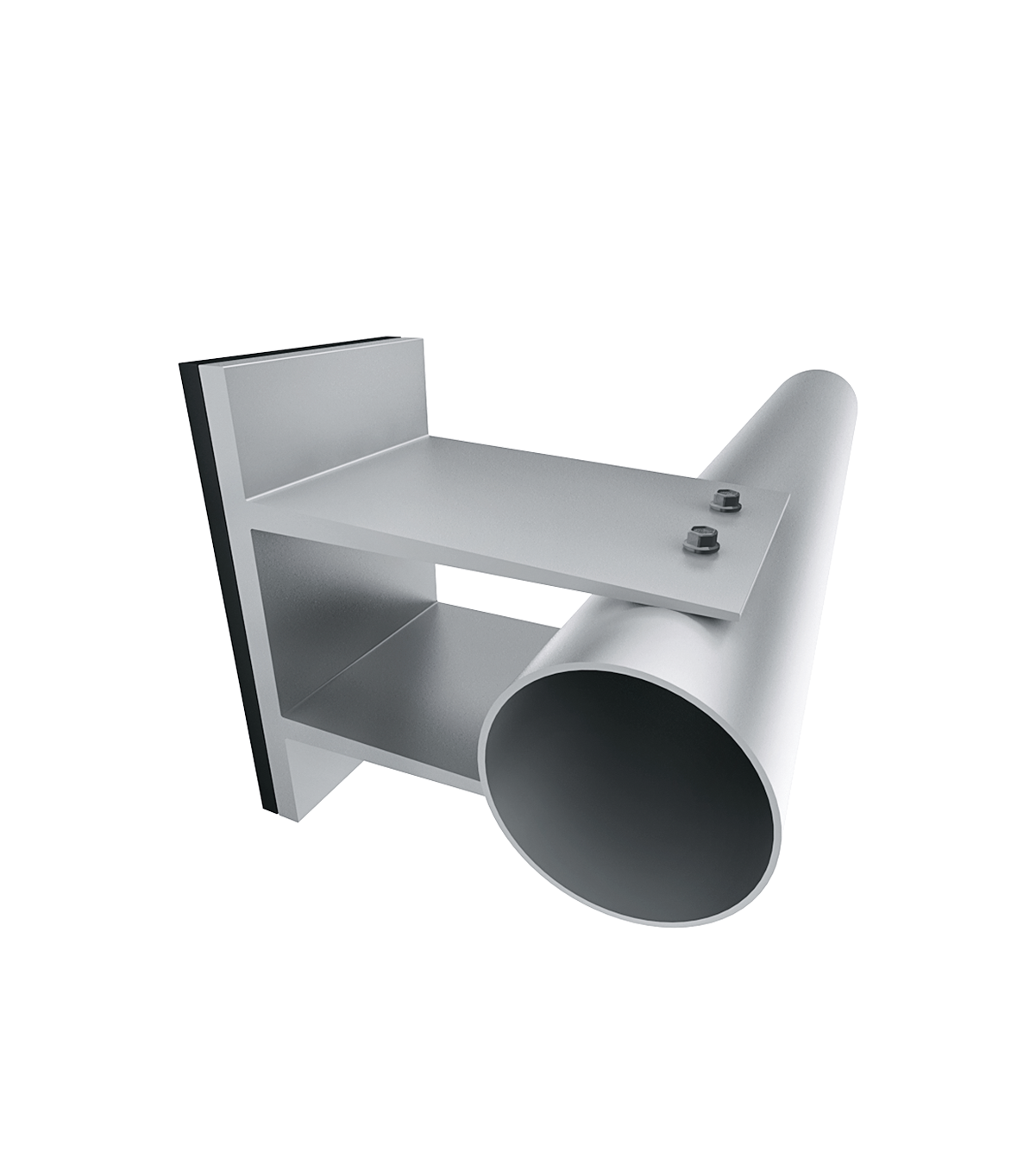

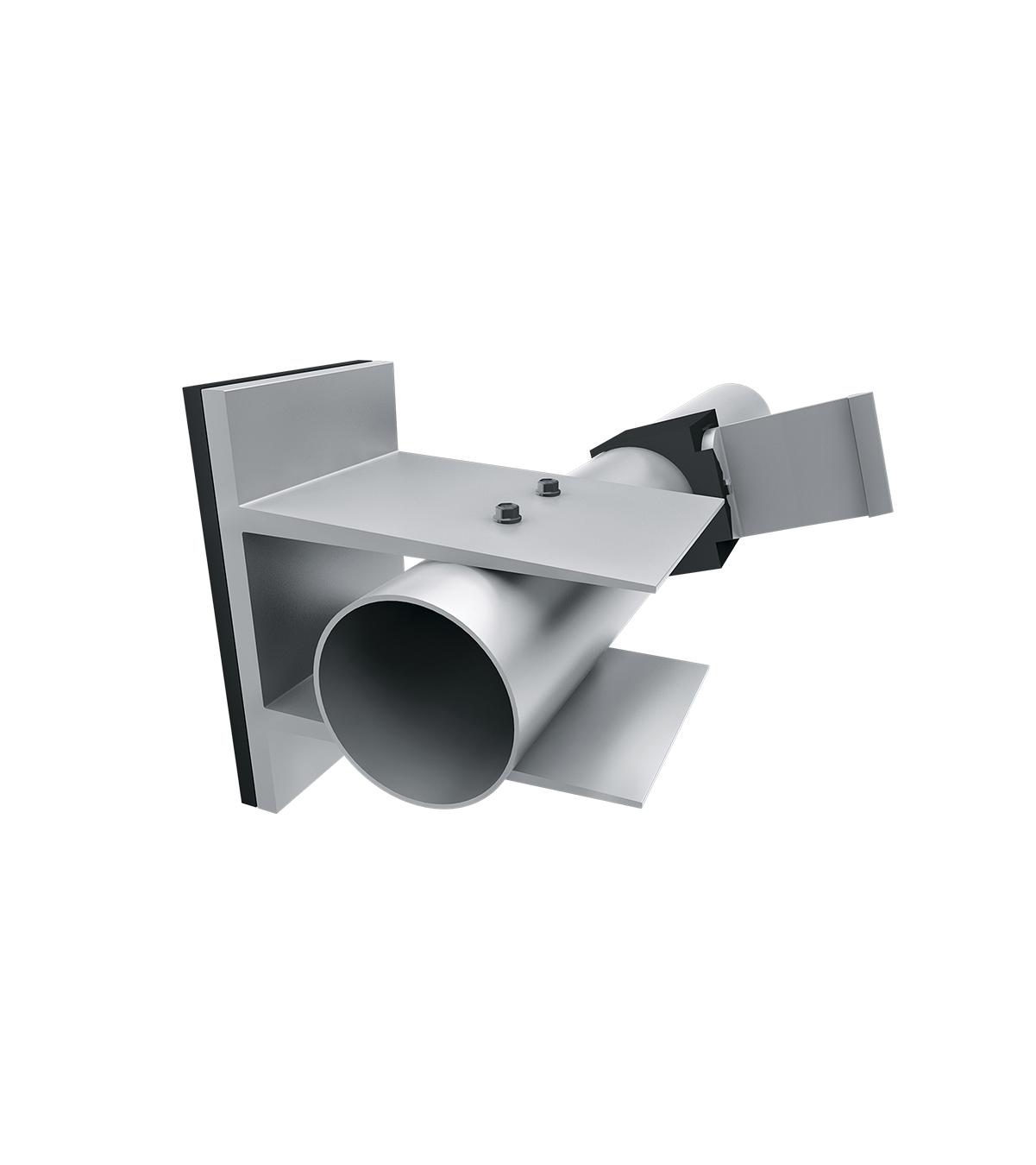

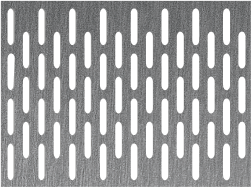

Façade bracket TEKOFIX-A++ for maximum reliability of rainscreen façades

The unique structure sets new standards in the area of thermal bridges

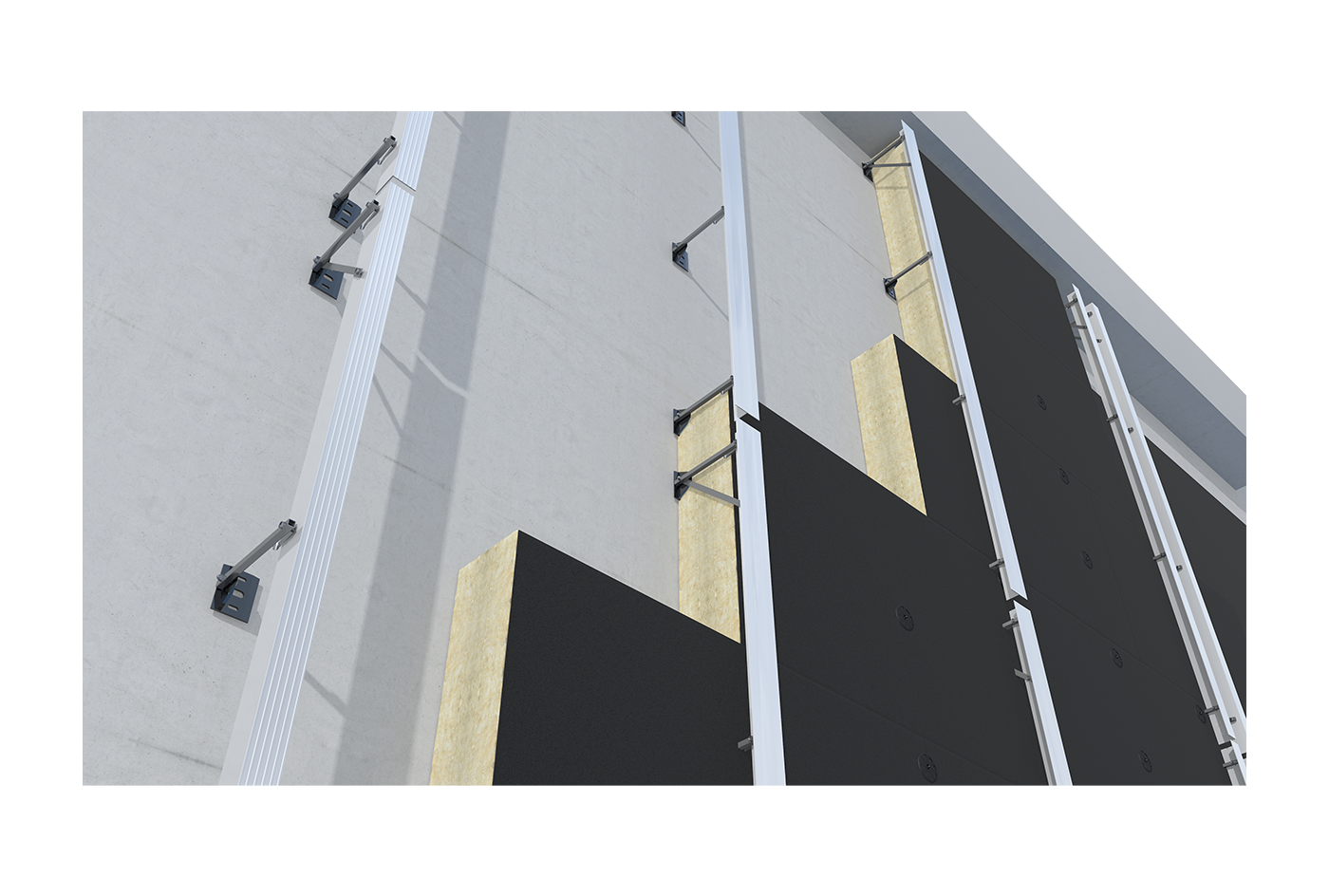

A unique bracket that sets new standards. TEKOFIX-A++ façade bracket guarantees the highest fire protection, the lowest thermal bridge impact and easy installation of rainscreen façades. Due to its unique stainless steel point design, the thermo console sets the highest standards in the area of thermal bridges and therefore easily reaches passive house level. Due to non-combustible components such as aluminium and steel, the façade bracket has the highest fire resistance rating and can also be used for rainscreen systems in high-rise buildings.

Depending on the design, there are two types of fixed points: Type 1 can be used up to approx. 20 kg/m² façade weight. Fixed point type 2 can also be used for solid and heavy façades, such as stone or ceramic. BEMO prepares U-value calculations for each project, as well as associated design and static calculations for the correct layout and anchoring of the substructure system.

TEKOFIX A++ Efficiency Console

TEKOFIX A++ Efficiency Console FP Type 1

TEKOFIX A++ Efficiency Console FP Type 2

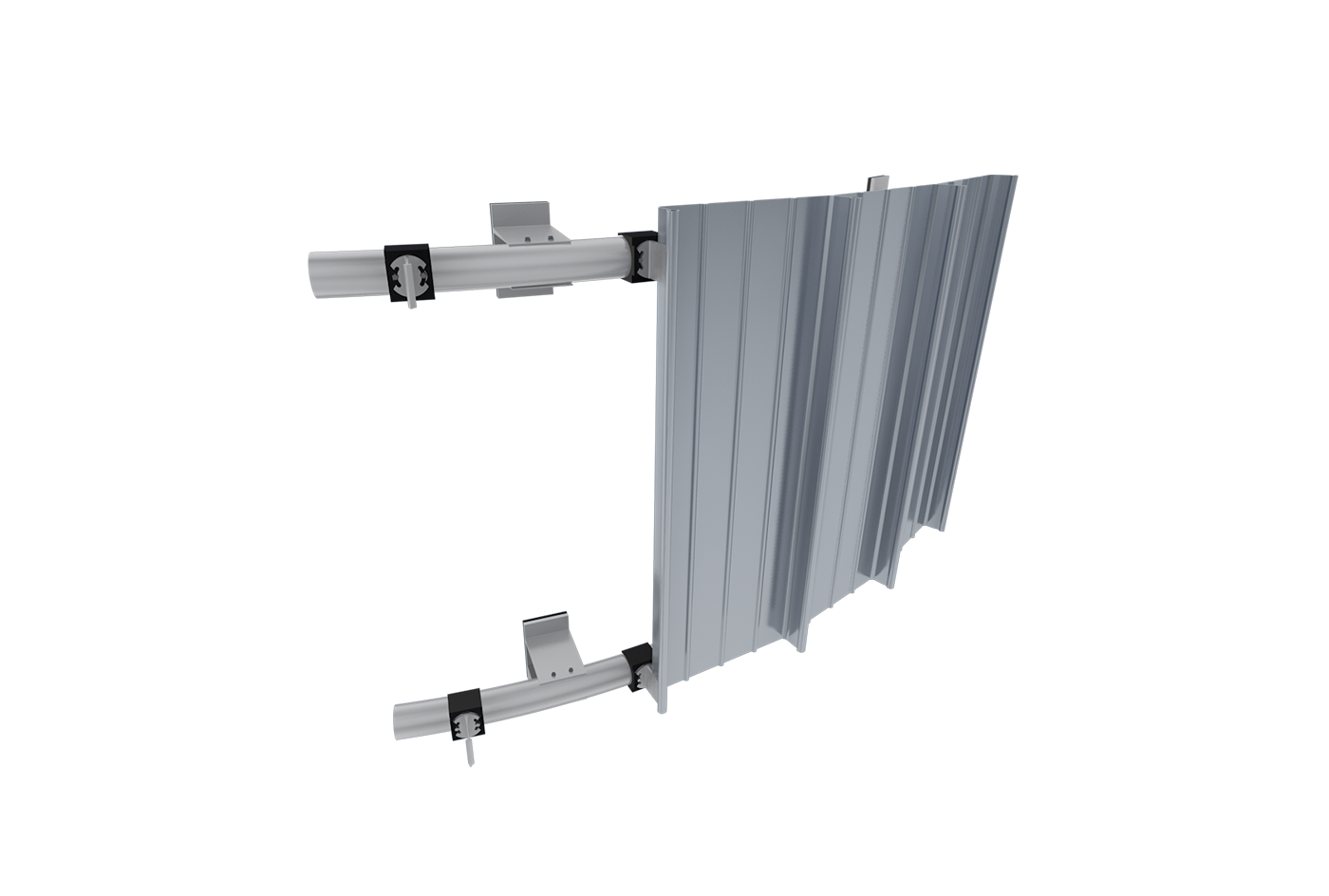

The BEMO-DOME flexible façade substructure

Can be used for various building shapes and as rainscreen substructures

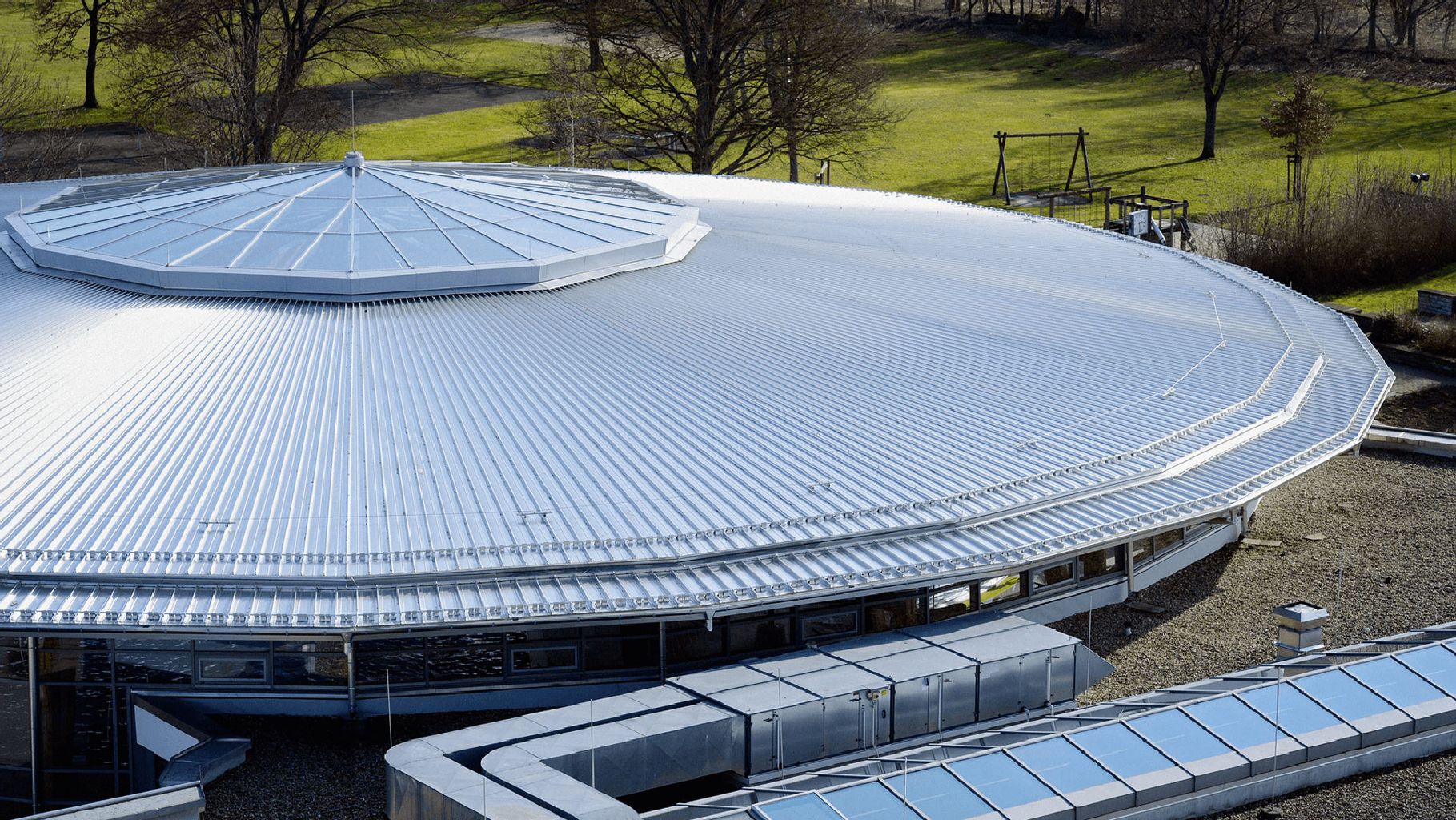

Whether for a rear-ventilated wall construction or unventilated, the BEMO-DOME façade substructure meets all requirements – also as a rainscreen system. To obtain a perfect result, we recommend the use of a 3-D scan for the on-site survey and execution design in 3-D for this substructure system.

The standardised system always consists of the same components and varies between round and square tubes and different brackets, depending on the design. Fastening of the roof substructure is possible on all substrates and offers a tolerance compensation of +/- 45 mm.

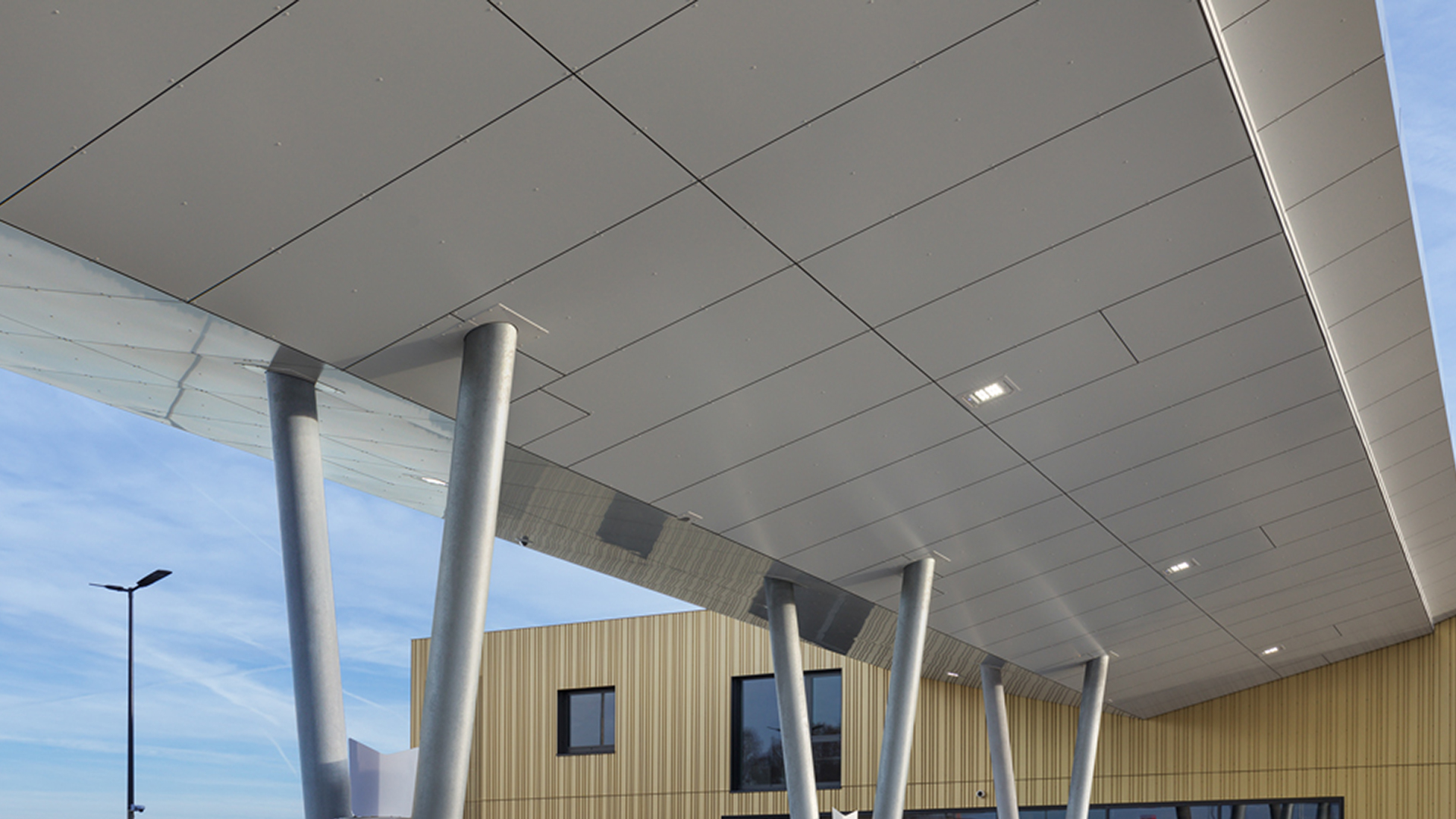

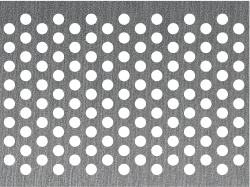

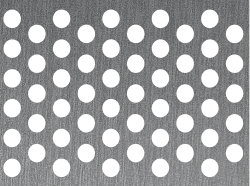

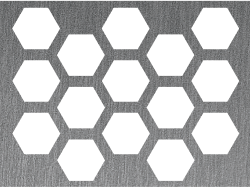

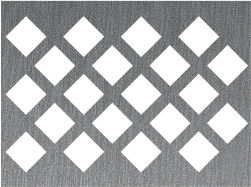

Endless design possibilities

Realize individual façade designs with BEMO

360° Service

Synergetic collaboration. Together through all project phases.

In our own planning office with system-experienced technicians and engineers who plan your projects with innovative and partly self-developed 3D technology, your ideas are professionally looked after from the start. We plan the implementation of your desired design, the material, and the design in synergetic cooperation with you and carry out the first technical details and static preliminary measurements for your rainscreen façade. But we also take on the complete implementation and workshop planning.

We create cost estimates, carry out technical optimizations or variant calculations and thus help you to optimize the profitability of your project. Well thought out from front to back – we use exact 3D measurements as the basis for our assembly-friendly systems and implementation in 3D planning. All of this is what defines the partnership with BEMO.