Smooth transition & free forms with the standing seam façade from BEMO

The right solution for new construction or renovation

Free forms, smooth transitions from roof to façade, and cylindrical and three-dimensional building shapes are increasingly required in modern architecture. A BEMO standing seam façade is exactly the right solution for this. BEMO standing seam impresses with many benefits, a variety of different systems and is suitable for both new construction and renovation.

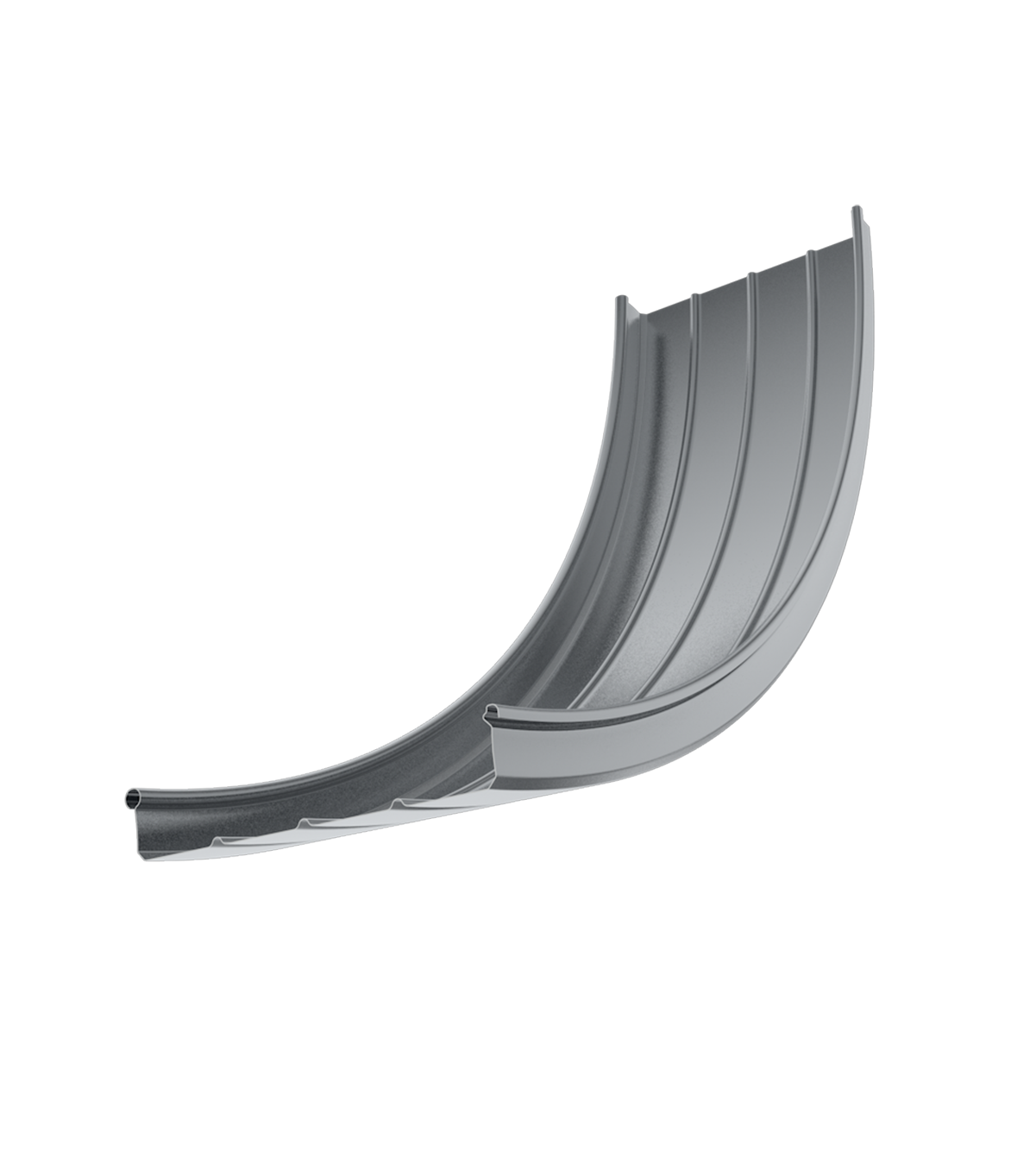

Different profile widths from 100 mm to 800 mm, 2 profile heights, almost infinite panel lengths, parallel, conical, and free-form profiles offer architects and designers a wide range of possibilities in the use of the standing seam façade. The standard materials used are aluminium and steel, but can be stainless steel, zinc, or copper. Radii for curved profiles start as low as 600 mm, depending on the choice of material.

Convex and concave radii are possible with the standing seam façade. The penetration-free and therefore invisible fastening leaves nothing to be desired and provides maximum safety. Length expansion takes place smoothly and permanently on the system brackets. BEMO standing seam brackets without thermal bridges optimise thermal insulation in low system structures. The standing seam system is completed by extremely variable, economical BEMO substructure systems for optimum tolerance compensation for any building shape, and of course all designed by the BEMO technical and design team.

-

Penetration-free fastening

for long-lasting stability -

Different widths of the standing seam profiles

from 100mm to 800mm -

Wide range of design options thanks to

different profile heights, panel lengths, parallel, conical and free-form profiles -

Thermal bridge-free brackets optimise

thermal insulation with low system construction -

Variable and economical BEMO substructure systems

for optimum tolerance compensation for every building shape -

Standing seam façades meet the highest demands

in terms of building physics and acoustics

BEMO façade profiles meet the very highest structural requirements

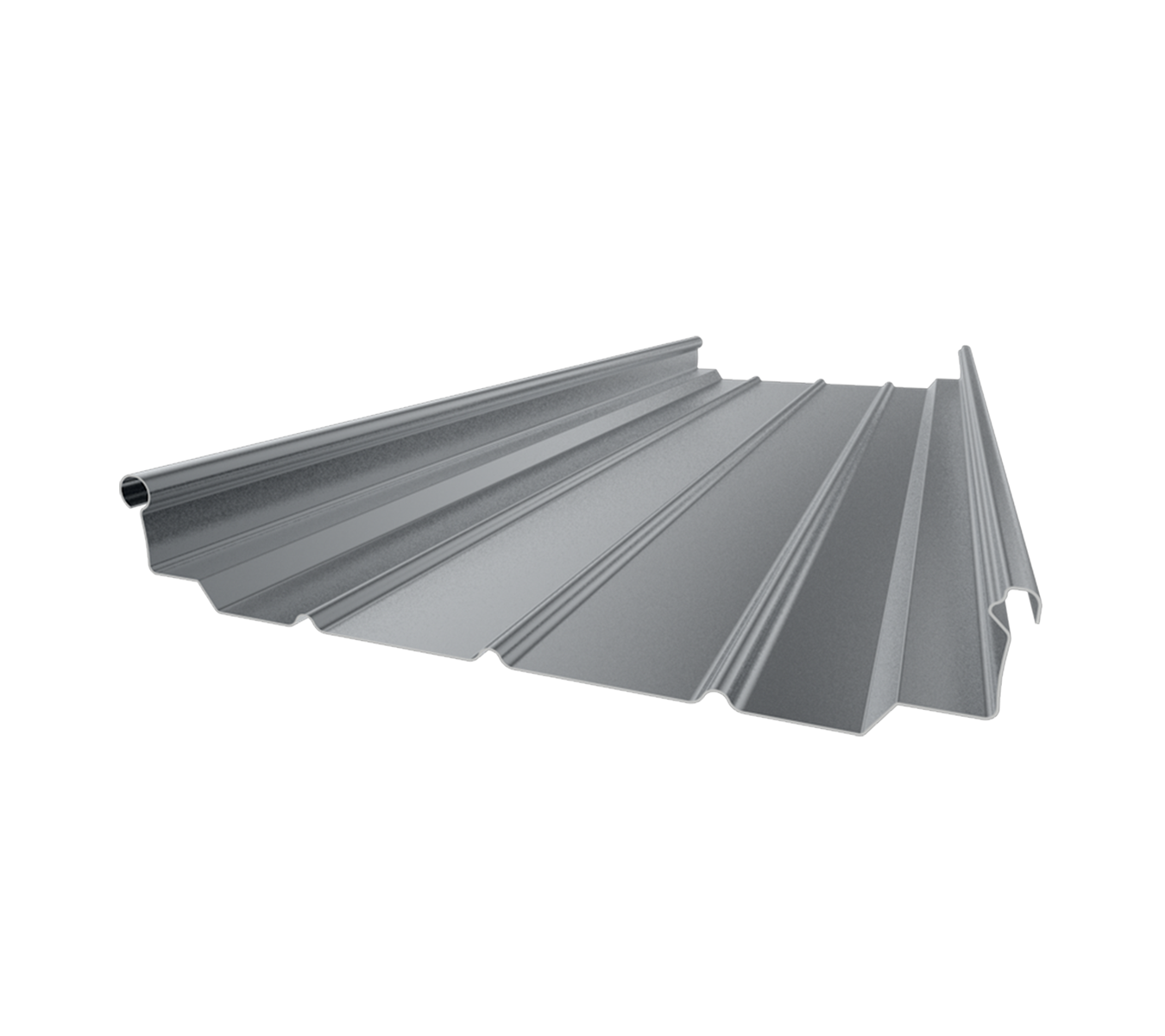

Straight or conical – free choice of shape and material of BEMO standing seam profiles

BEMO standing seam profiles ensure maximum safety for building cladding. Even in special shapes, BEMO façade profiles guarantee full functionality. Our standing seam façades also meet the highest demands in terms of structural soundness and acoustics. On top of that, they can be used for almost any shape of building. The visual design possibilities are many and varied. You have free choice of profile shape, metal, surface, and colour. By interlocking onto special standing seam holders, a penetration-free installation is also ensured.

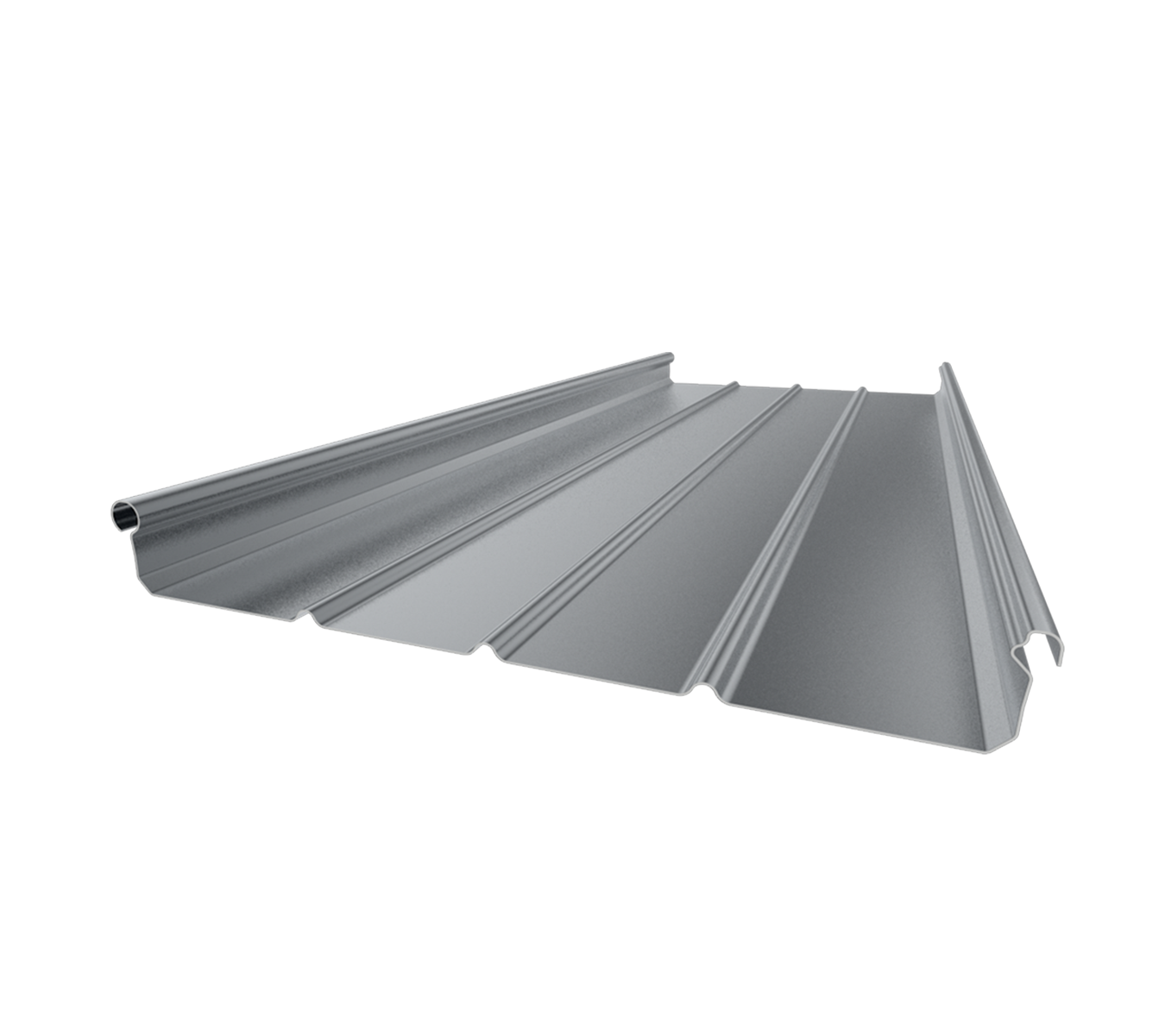

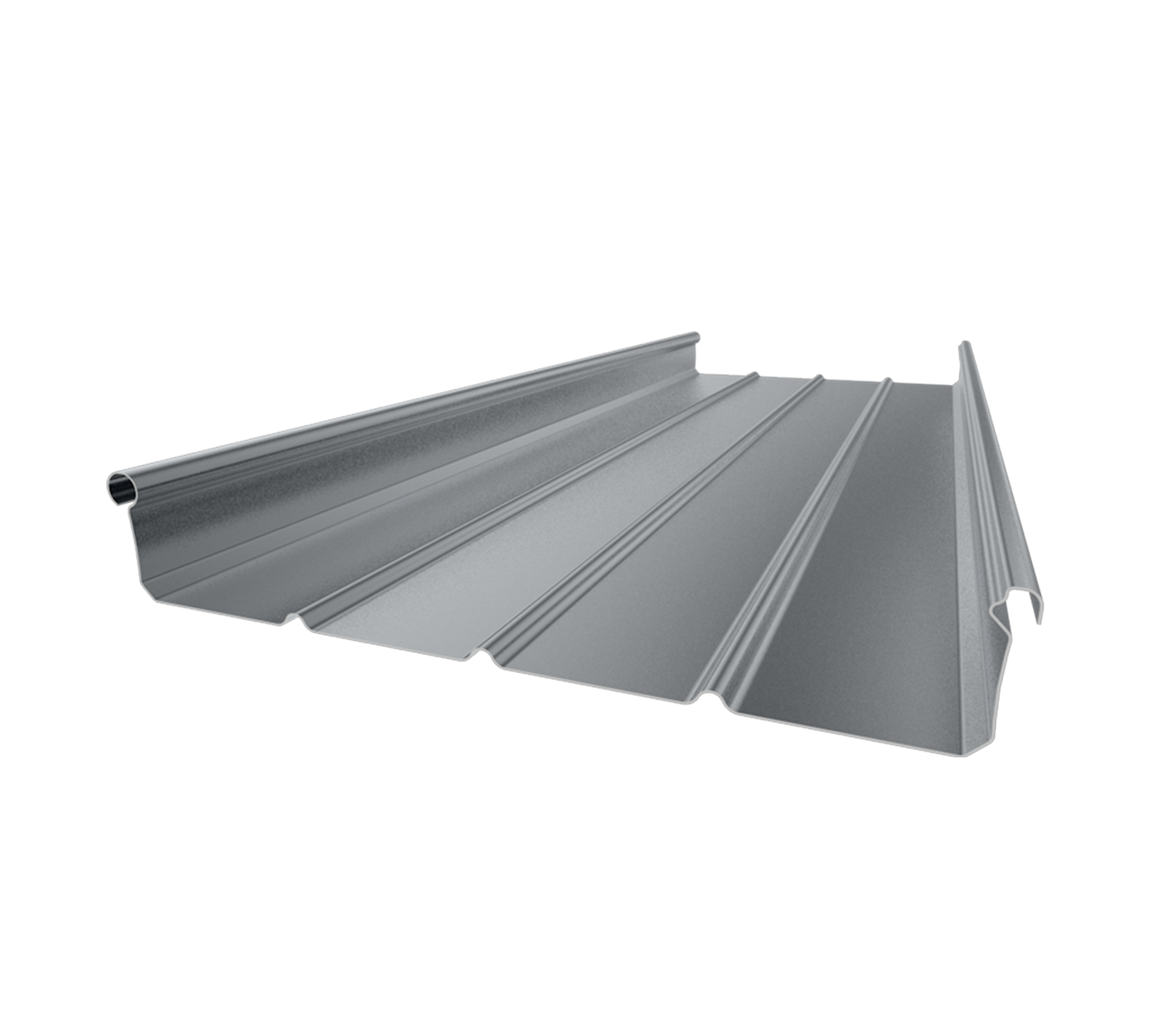

The three proven profile variants can be selected as façade profiles for all materials:

N 50 – the profile with 50 mm seam height and variable profile widths. It is often used for smaller roof areas such as monopitch roofs and residential buildings, as it has a particularly subtle and aesthetic appearance. The façade profile is also in demand for industrial roofs without high snow loads.

N 65 – the profile with 65 mm seam height and variable profile widths. Due to the seam height of the façade profile, it is particularly suitable for flat sloping roofs. It also has a very good load-bearing capacity and therefore good structural values.

VF 65 – the profile with 65 mm seam height and variable profile widths. This façade profile is ideal for use on rigid insulation and wooden boarding, where it is laid over the entire surface. The geometry of the bracket foot accommodates special mouldings without imprinting.

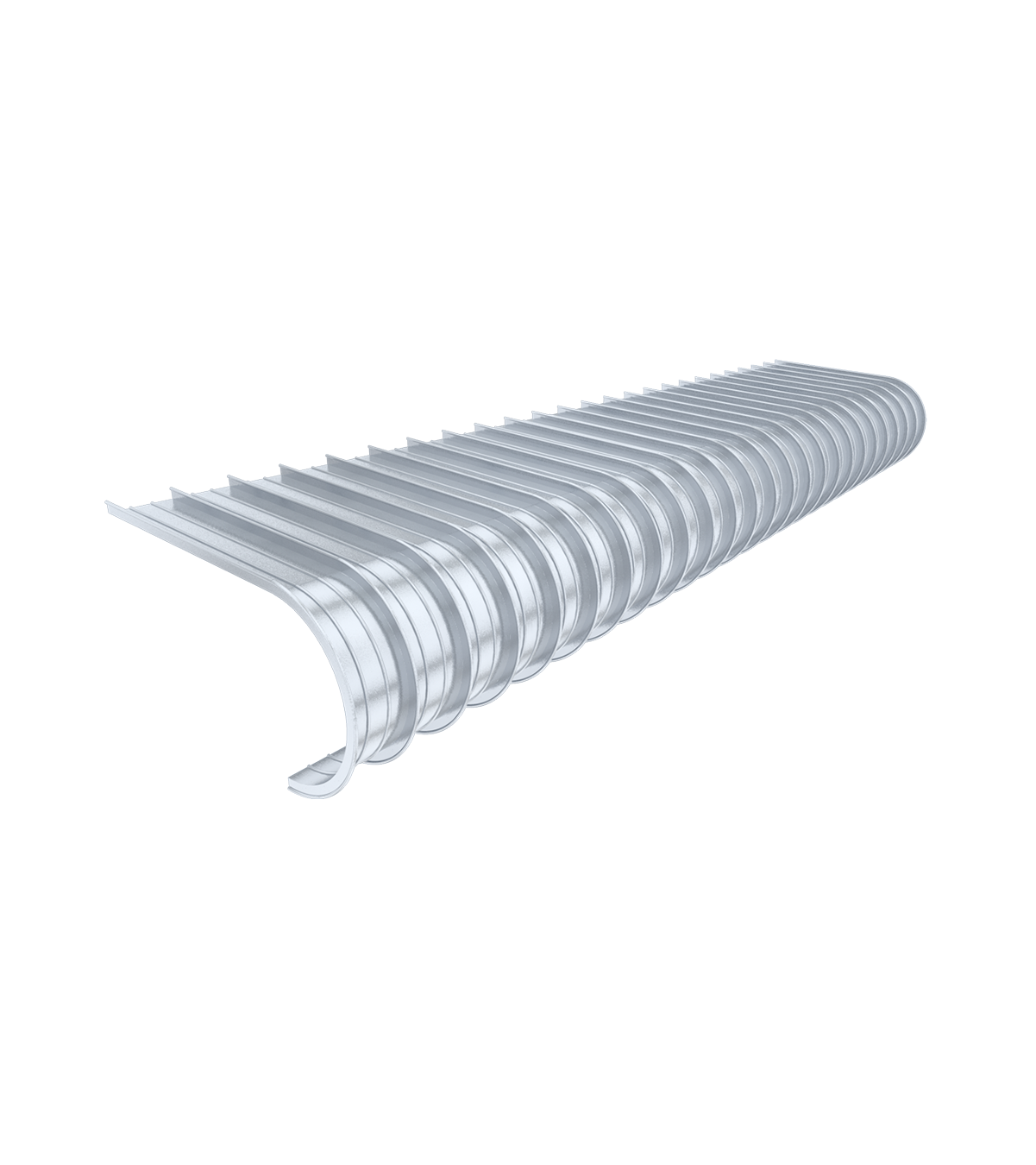

BEMO-MONRO® for a flexible standing seam façade covering

High adaptability for free-form buildings with BEMO-MONRO®

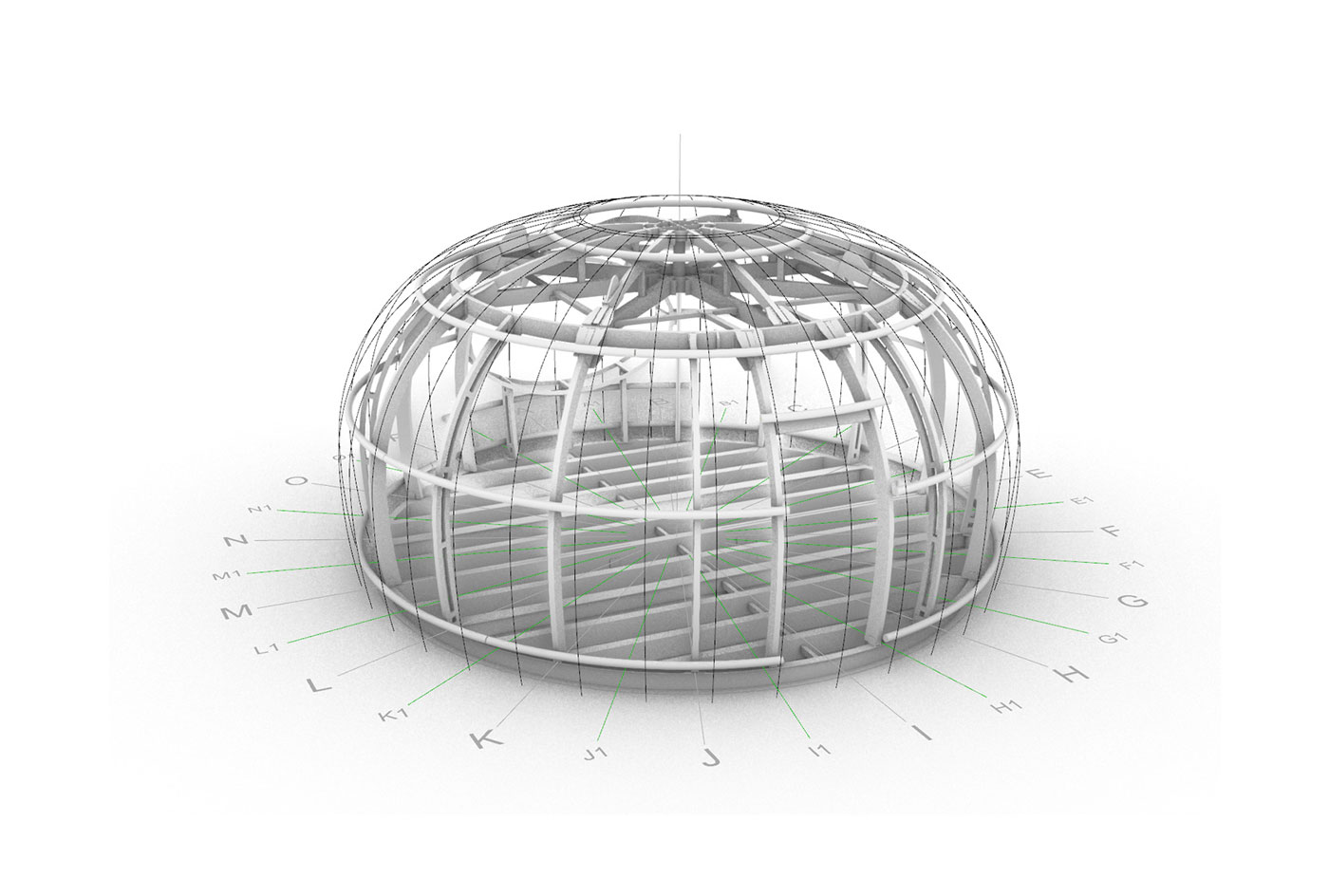

The MONRO® system is generally combined with a substructure that is adjustable in three dimensions. This allows unevenness in the supporting structure to be corrected easily and efficiently. BEMO 3D design plans the standing seam system ready for installation in the standing seam roofing of the façade.

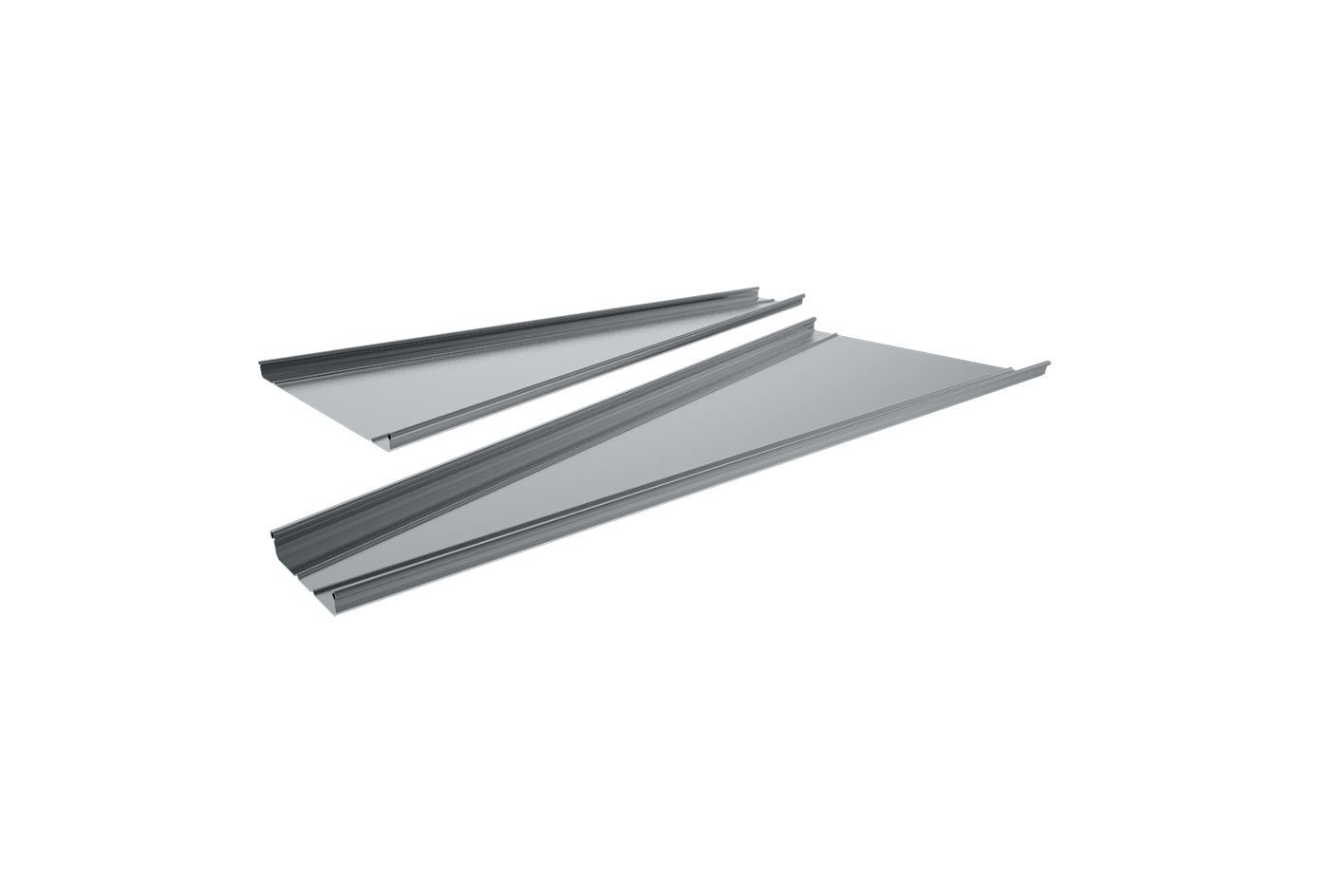

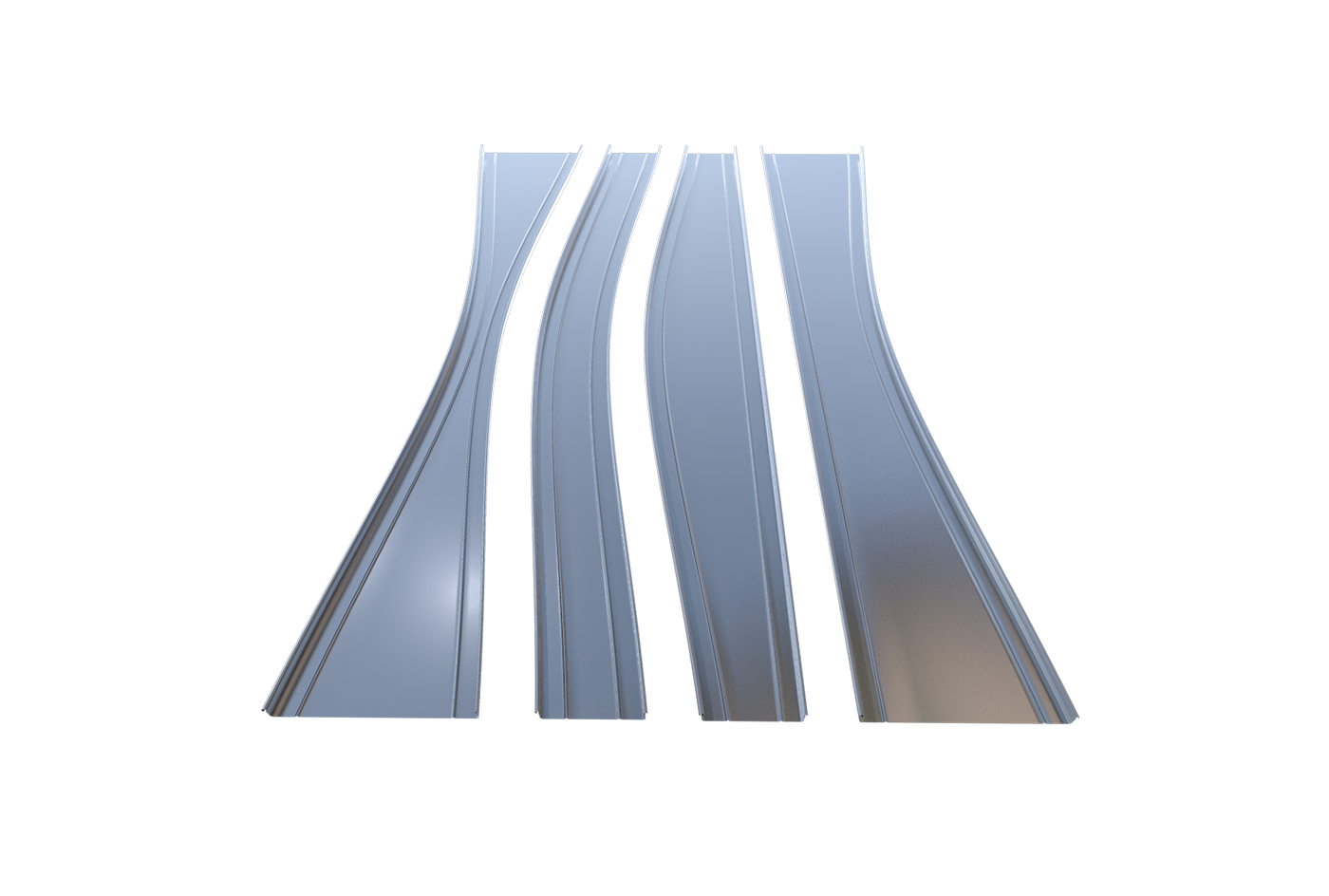

For larger circular and conical buildings, special conical profiles are used. With a minimum width of 100 mm and a maximum covering width of 800 mm, these special profiles allow almost any requirement to be implemented. Because the standing seam sheets for the façade are formed to fit precisely in a single work step, there is no need for time-consuming trimming during the project.

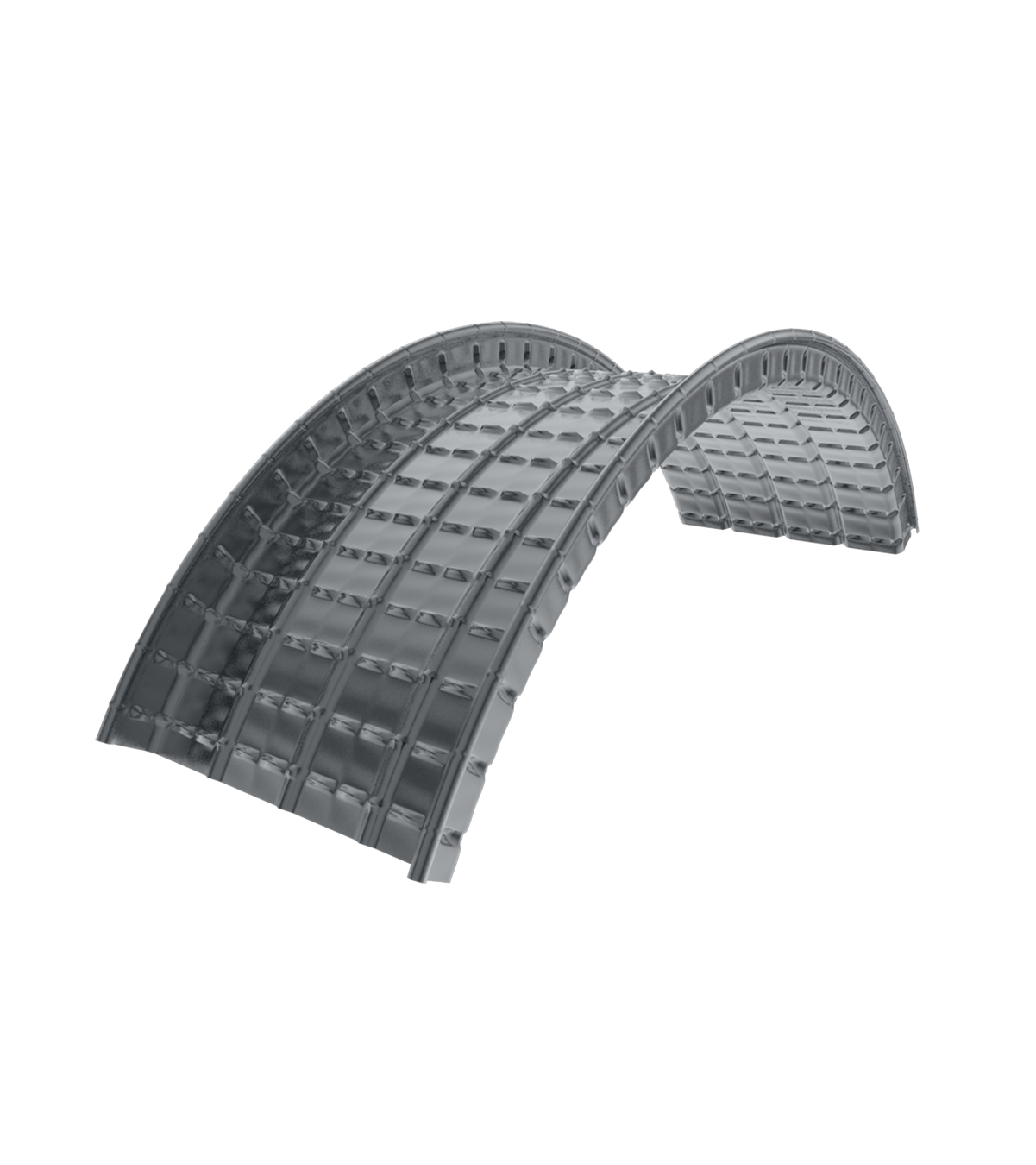

All BEMO special profiles are also offered in curved shapes and in all materials.

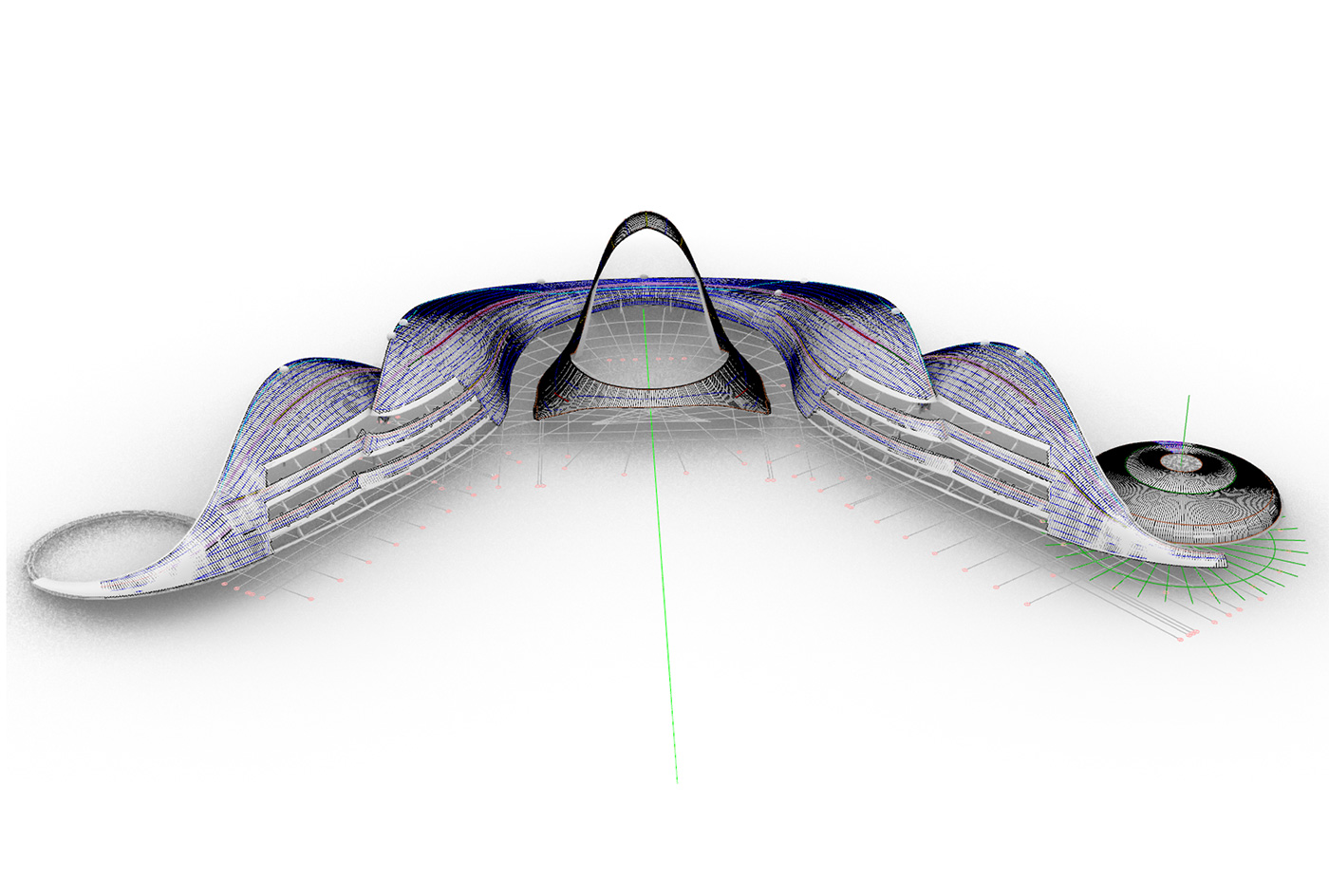

Planning flowing façades sensibly

Our team of experts will be happy to assist you in planning your free-form architecture project. Using comprehensive analyses and innovative 3D planning, our BEMO expert planners create geometries and surface optimizations of any facade shape.

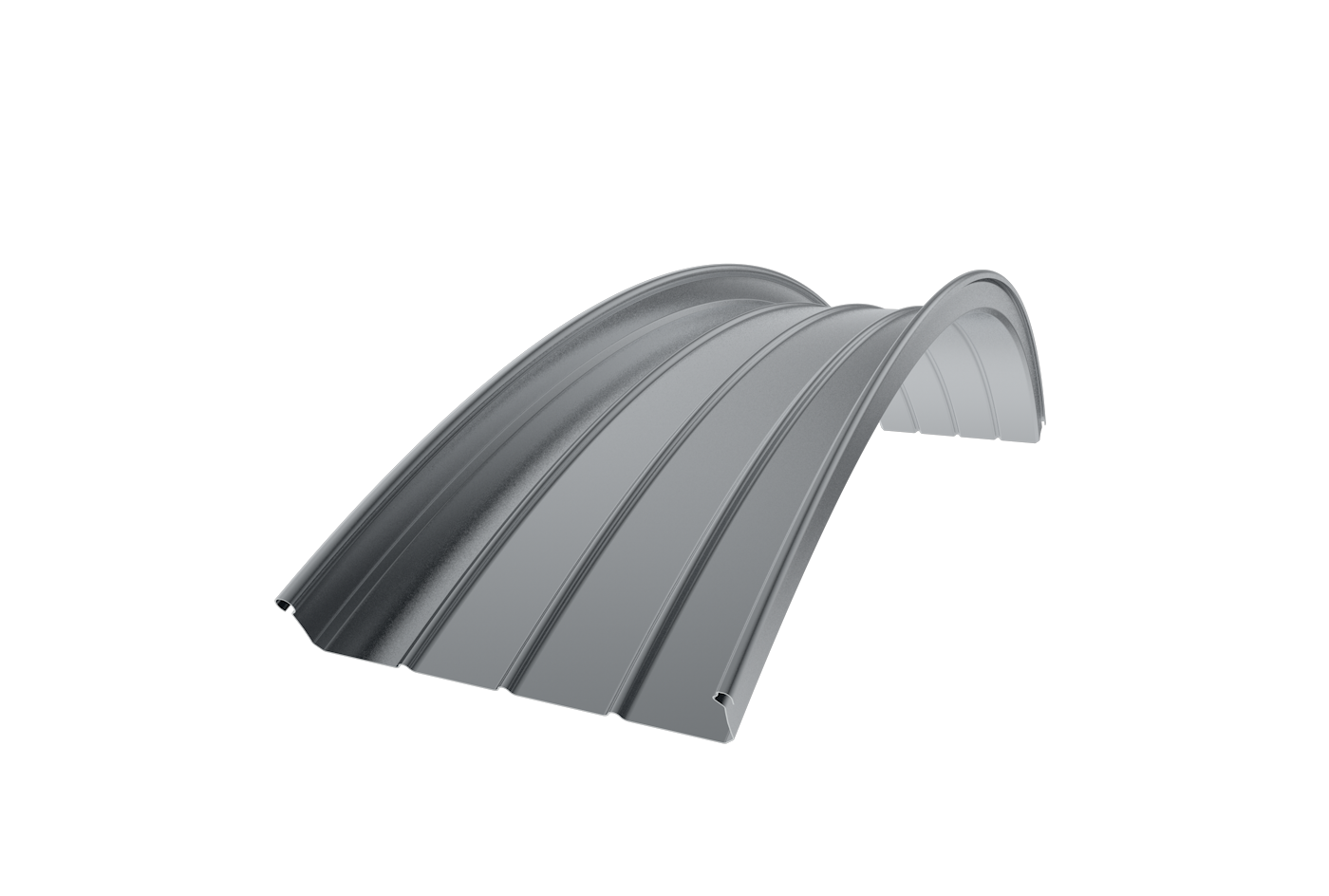

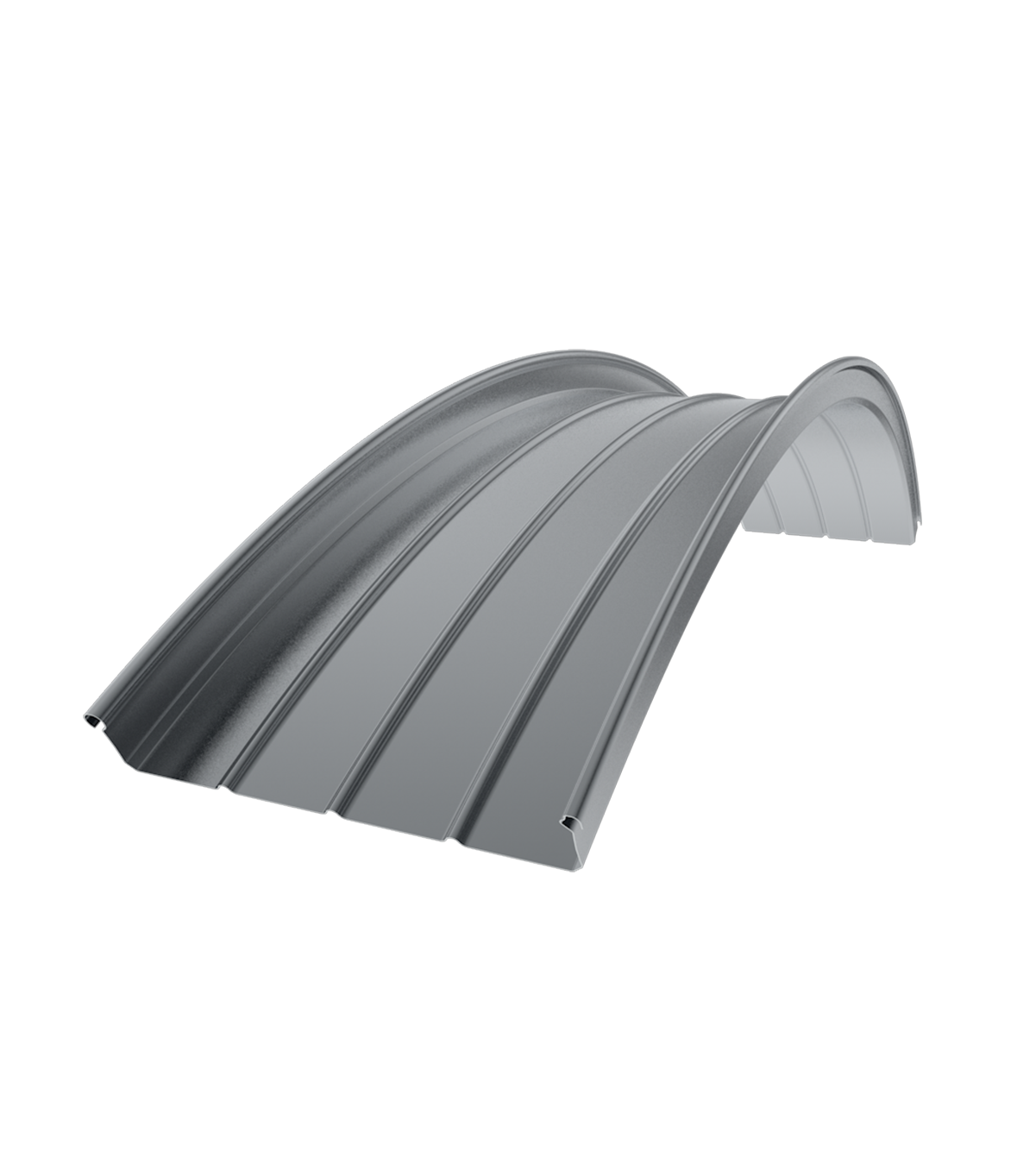

Curved façades with curved standing seam panels

Precise fit of the standing seam sheets by BEMO directly on the structure

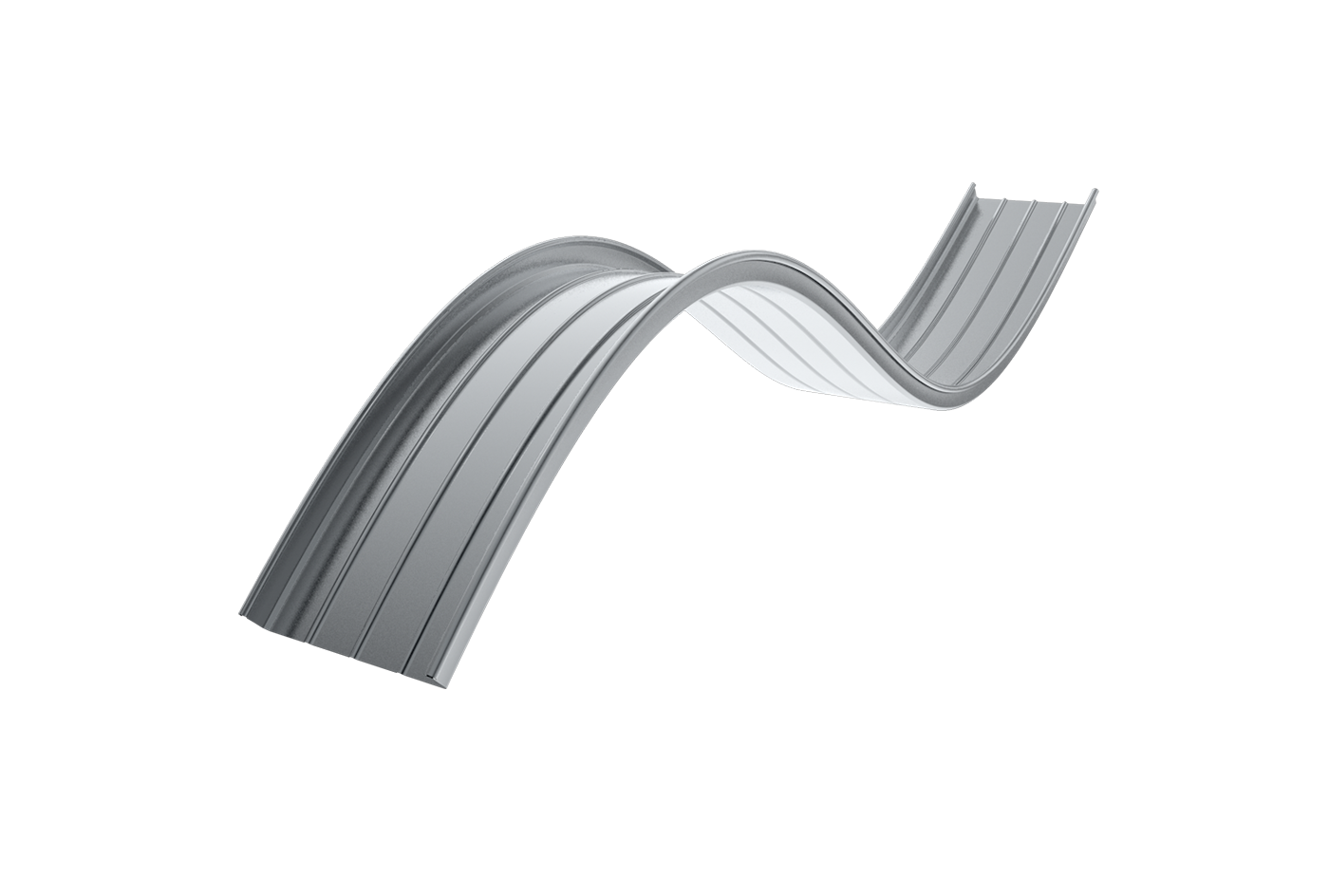

For a curved standing seam façade, the curvature can be either concave, convex or concave-convex. Curving down to the smallest radii is possible. Depending on the material and profile, minimum radii of less than 800 mm are feasible for us.

All BEMO profile variants can be used for subsequent curving. This ensures that even with a curved façade, complete functional safety of the products is guaranteed. Tolerance compensation is also possible using BEMO substructure systems BEMO-Dome or BEMO-Flex. We also recommend a 3D survey of the entire building shape as well as the use of the BEMO execution design in 3D.

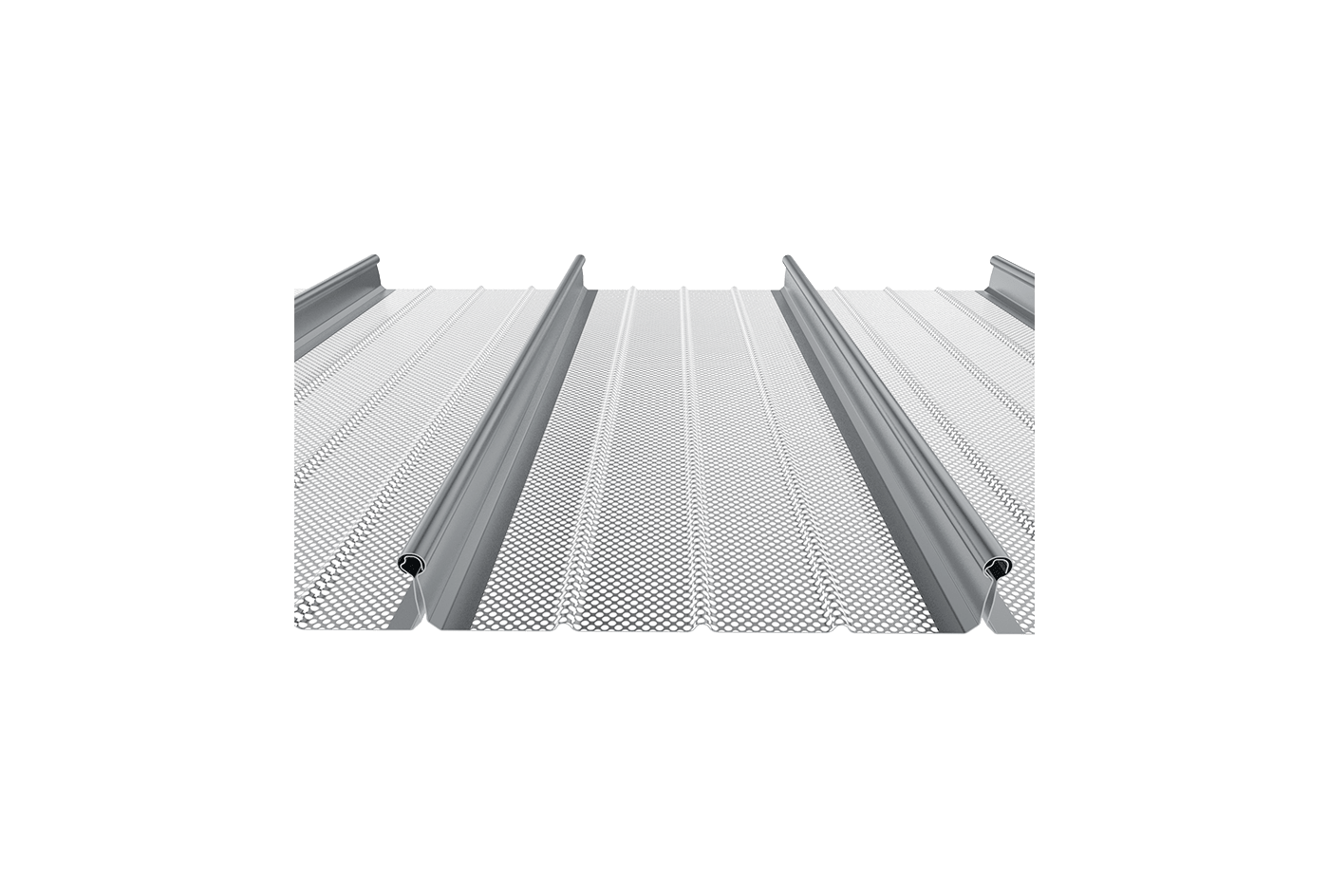

Perforated façades with BEMO standing seam profiles

Protection and design freedom with perforated standing seam façades

Panel seams come in two versions: with unperforated seams or fully perforated for free-form profiles.

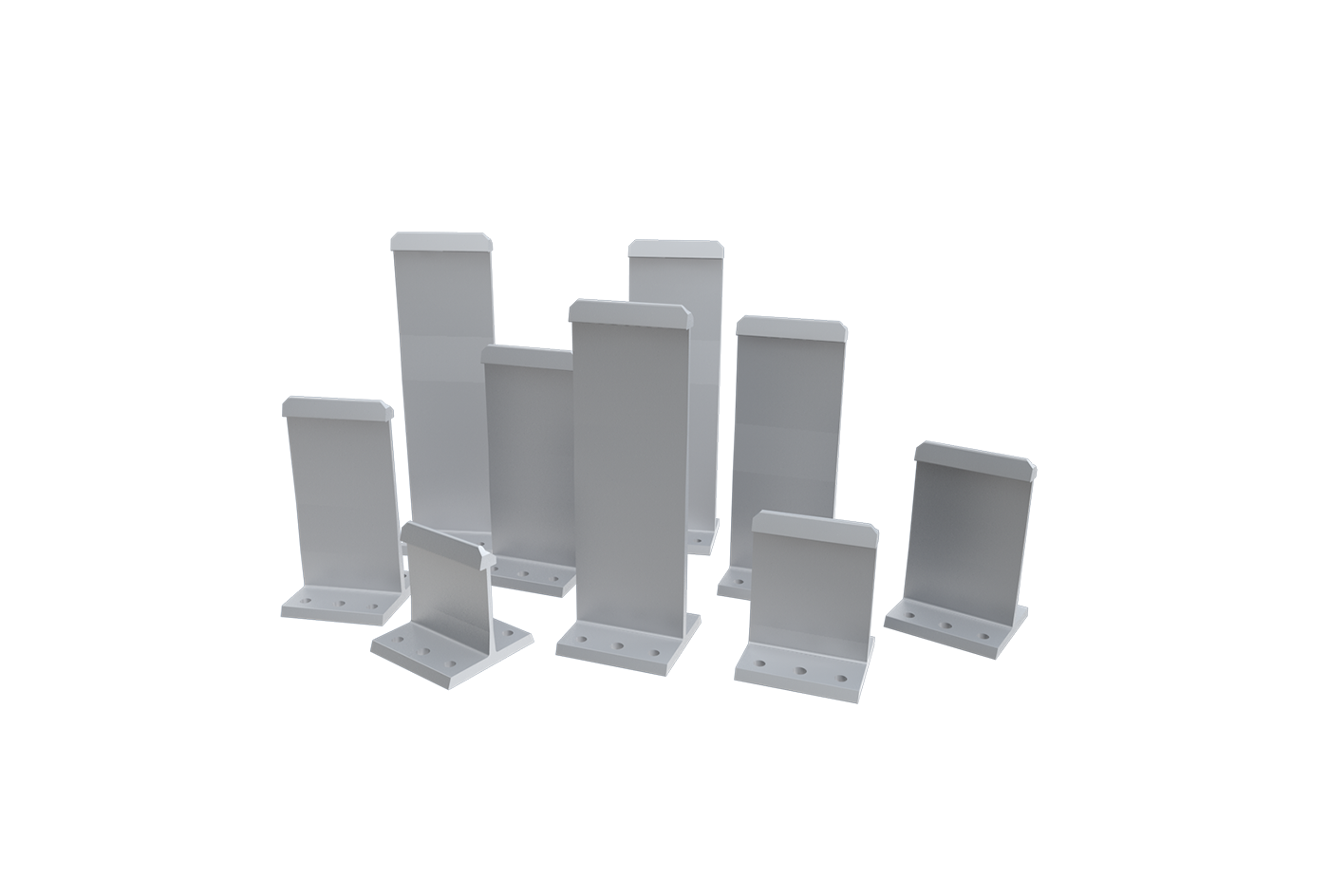

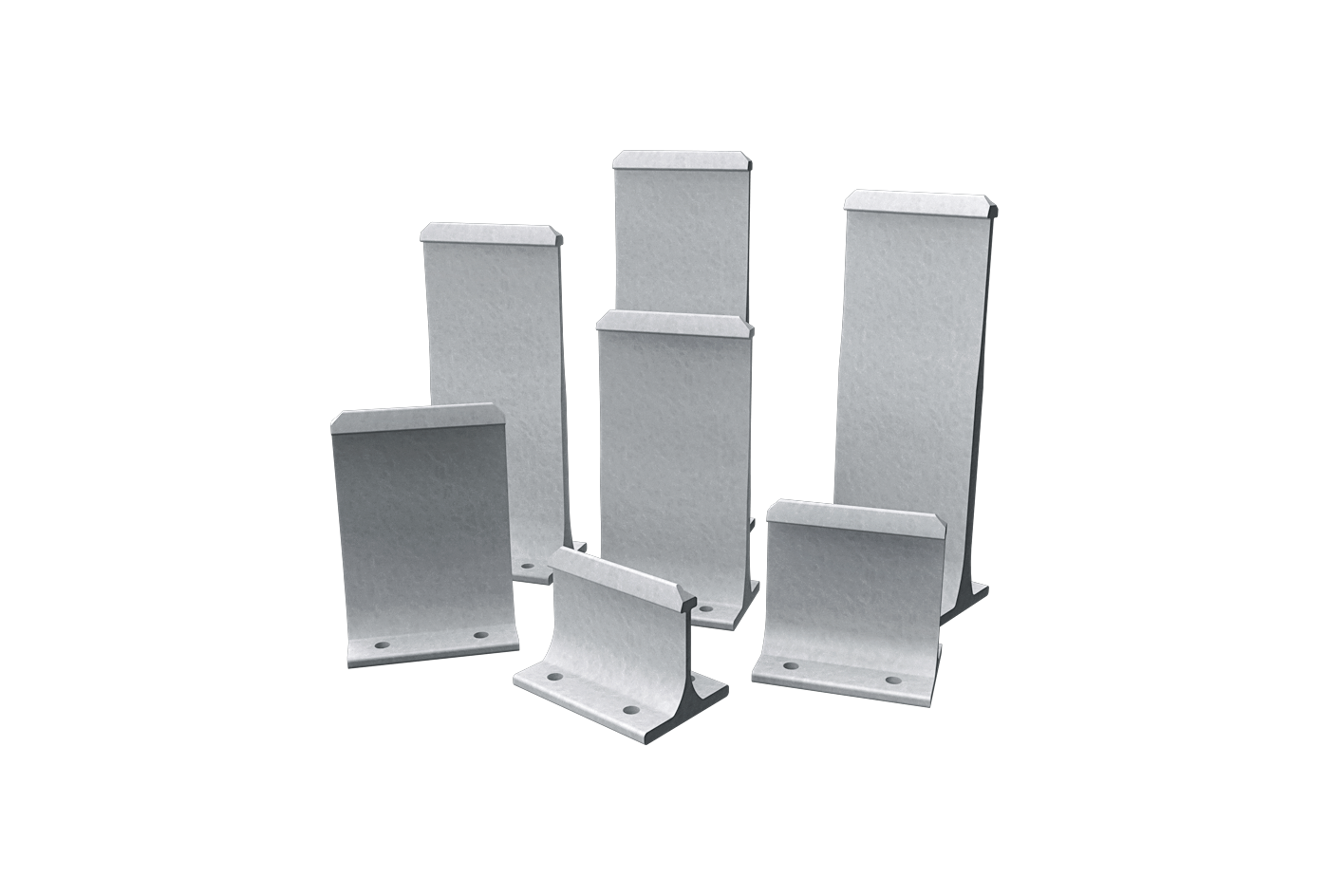

Bracket systems for standing seam façades

High load-bearing capacity of the façade with brackets from BEMO made of aluminium or GFRP

The free sliding movement of the standing seam sheets during thermal linear expansion is one of the most important properties of a BEMO standing seam façade. For this purpose, the façade needs halters that ensure optimum load-bearing capacity. BEMO aluminium brackets are specially designed for optimum sliding behaviour due to their rounded corners. BEMO thermal caps TK 5 and TK 15 attached to the foot of the bracket provide thermal decoupling.

Bracket in fibreglass-reinforced plastic (GFRP)

For a thermal bridge-free structure that sustainably reduces energy costs

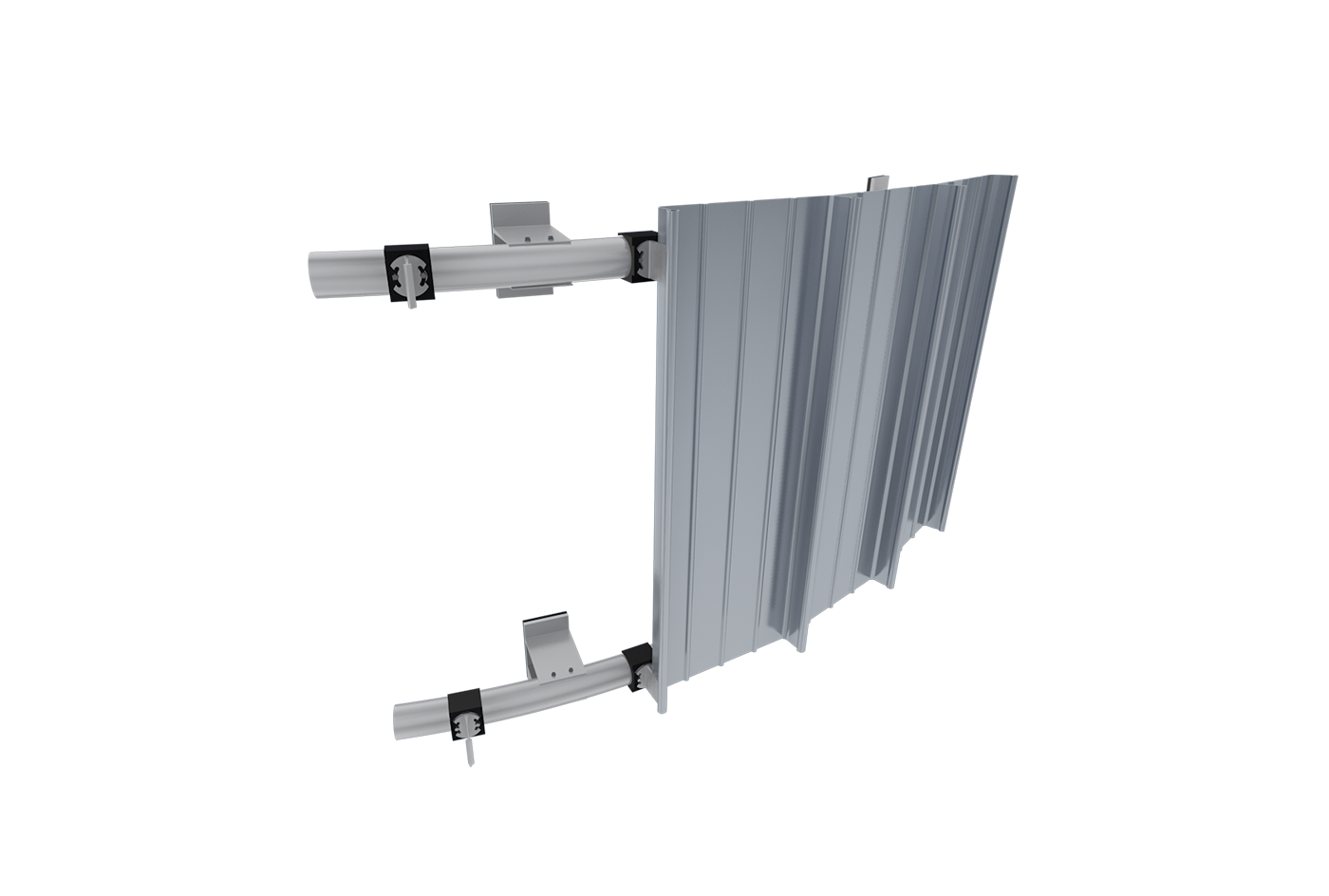

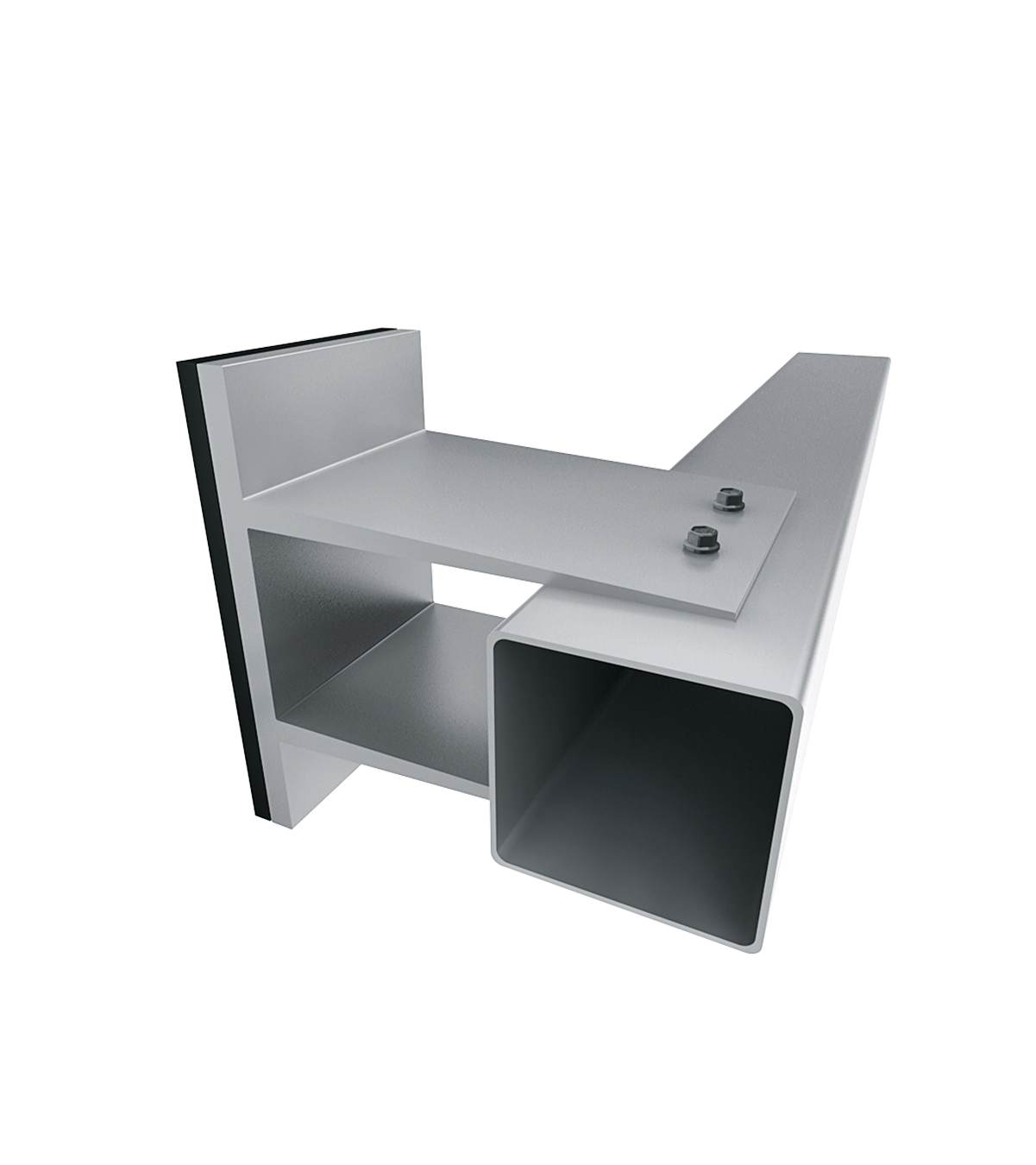

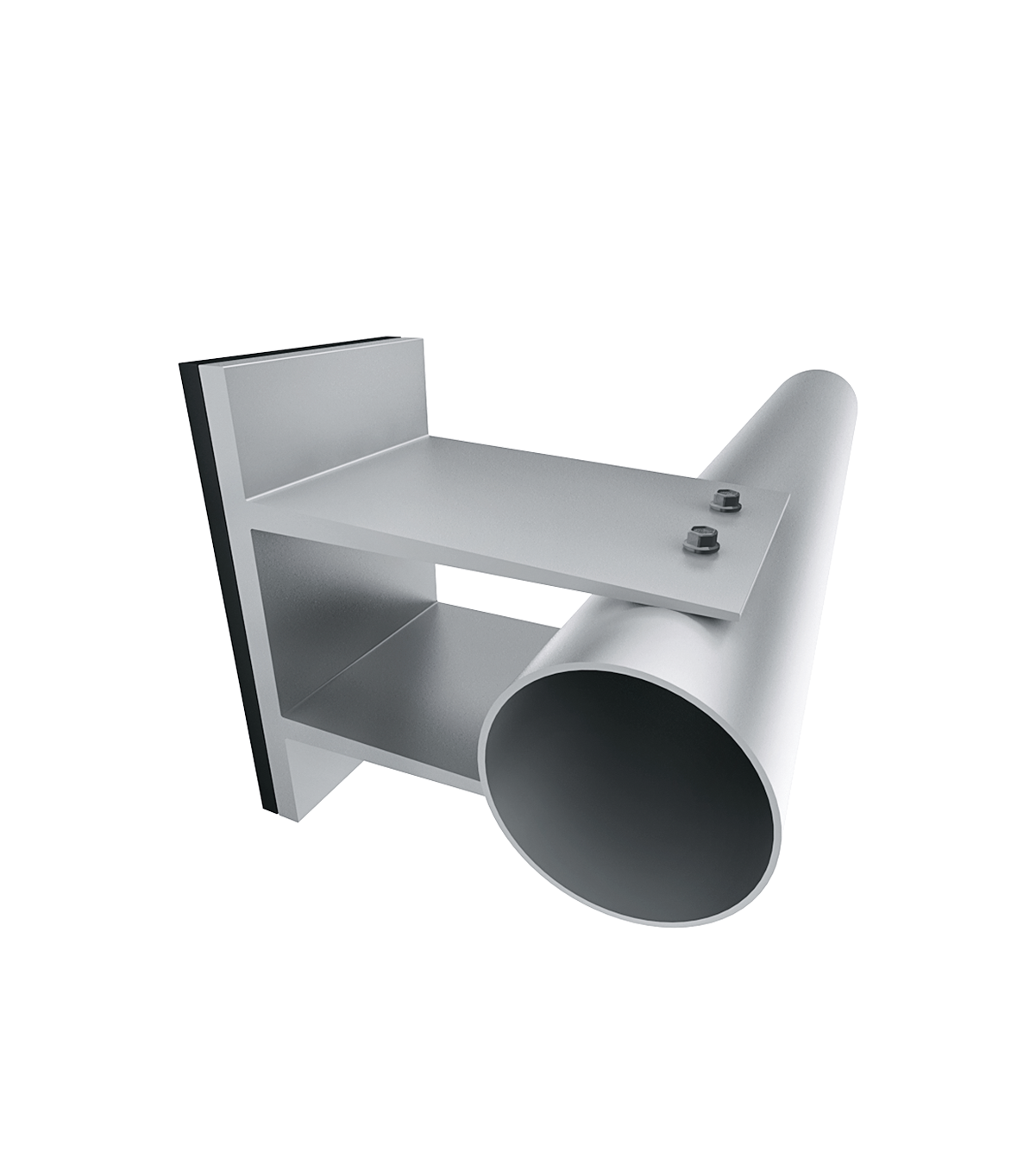

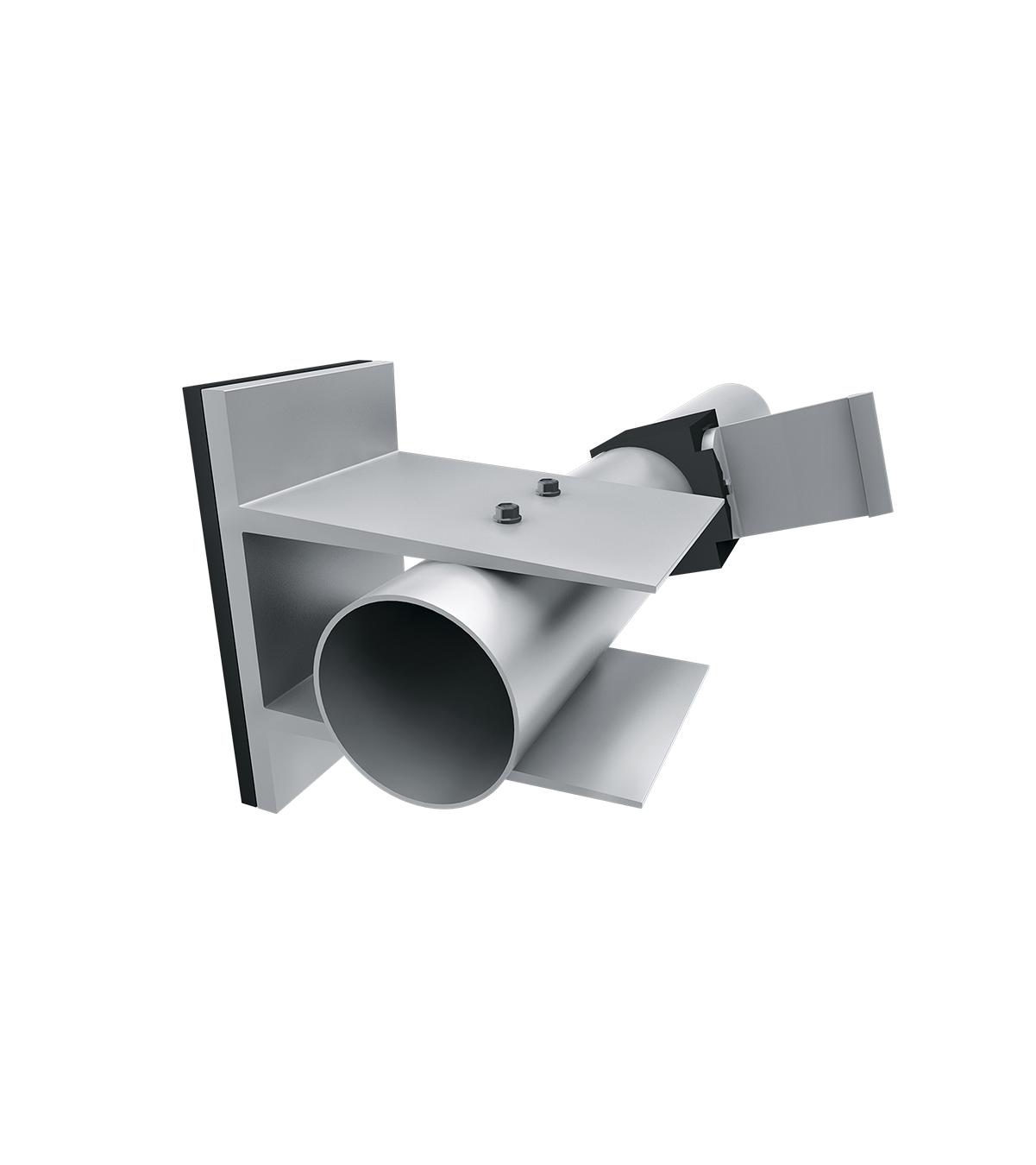

The BEMO-DOME flexible standing seam façade substructure

As rainscreen substructures and for various building shapes usable

As a rear-ventilated wall construction or unventilated the BEMO-DOME façade substructure can meet all regulations- also as a rainscreen. For a perfect result, the use of a 3-D scan for the on-site survey and execution design in 3-D for this substructure system is recommended.

The standardised system always consists of the same components. It only varies between round and square tubes and different brackets, depending on the design. The façade substructure can be fastened on the most diverse substrates and offers tolerance compensation of +/- 45 mm.

Inspiration

Aviva Studios (Factory International)

Sports hall Schorlemerstraße

Elementary school Längenfeldgasse Vienna

Lorentz Leiden Towers

360° Service

Turning challenges into innovative projects with enthusiasm. That is what sets us apart.

BEMO is passion and joy – especially in meeting any challenges with new ideas and thereby implementing individual projects. We turn every challenge into a unique approach. You can feel the passion of our experts right from the start: From the conception phase on, our experienced project consultants support your projects and pave the way for unique standing seam façades. We are also the experts at your side in the planning phase and take responsibility for any system-relevant questions. For us, 360 ° service not only means taking responsibility, but also guaranteeing the success of the project. Our extensive network of cooperation partners helps us to act globally, and your projects benefit from it, especially in material provision and delivery logistics. We can always count on our long-term partners.

We work together as a team, with you and our partners. Promised.