Inspiration

Aviva Studios (Factory International)

Koblenz Handwerkskammer Mensa

Firmengebäude Memmingen

Gefahrenabwehrzentrum Gießen

Produkte

360° Service

Individuelle Projekte mit BEMO realisieren

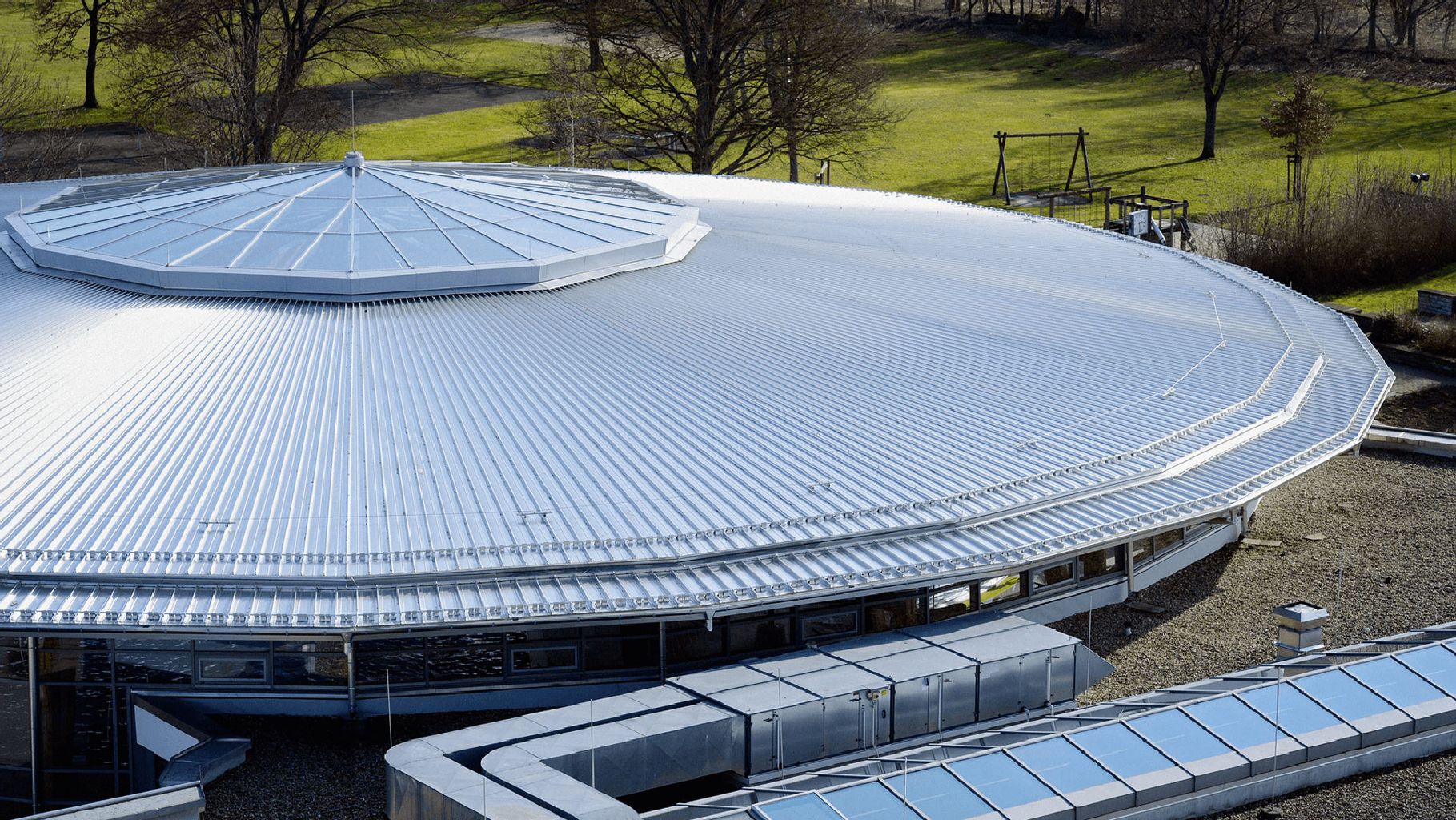

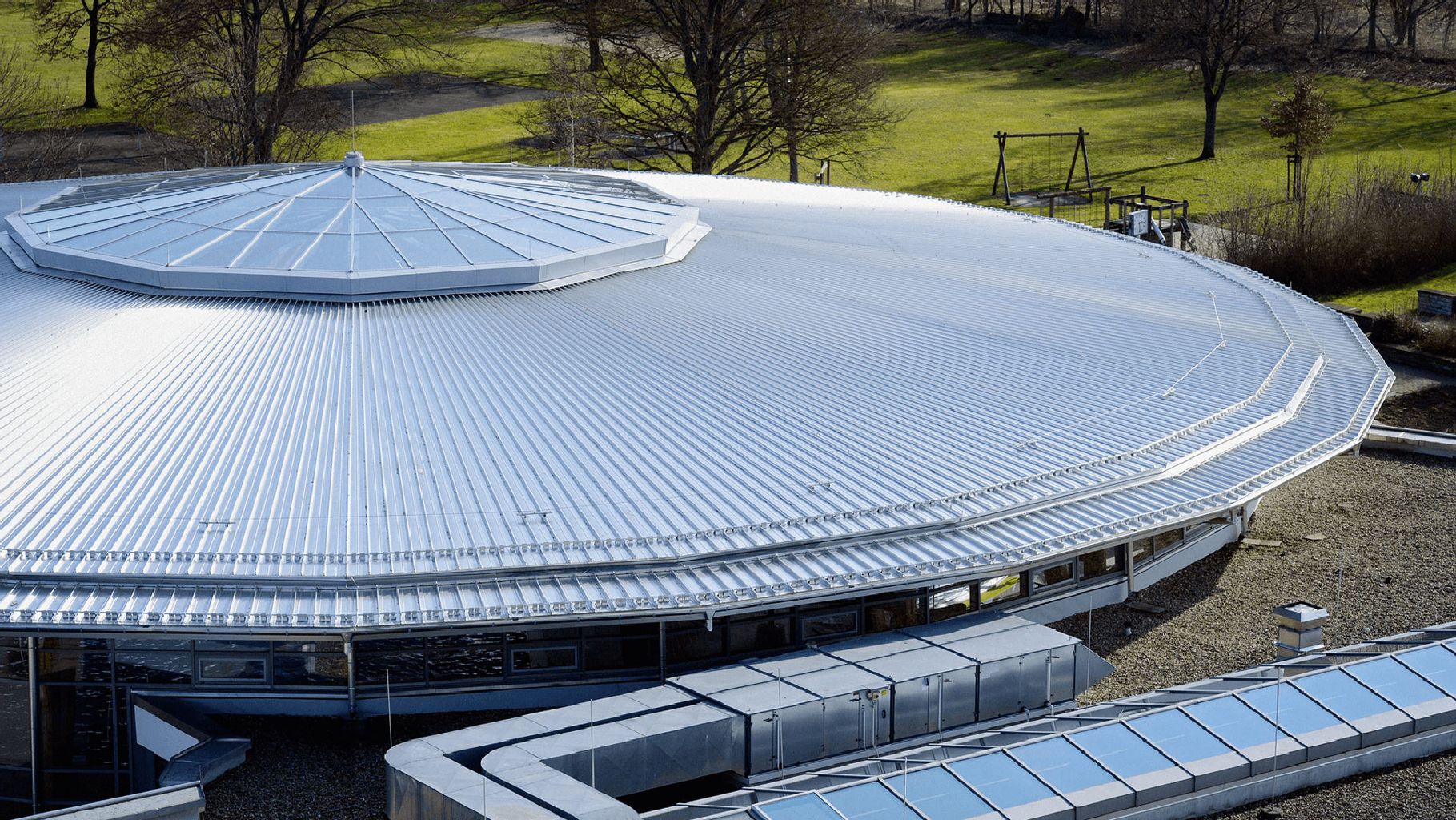

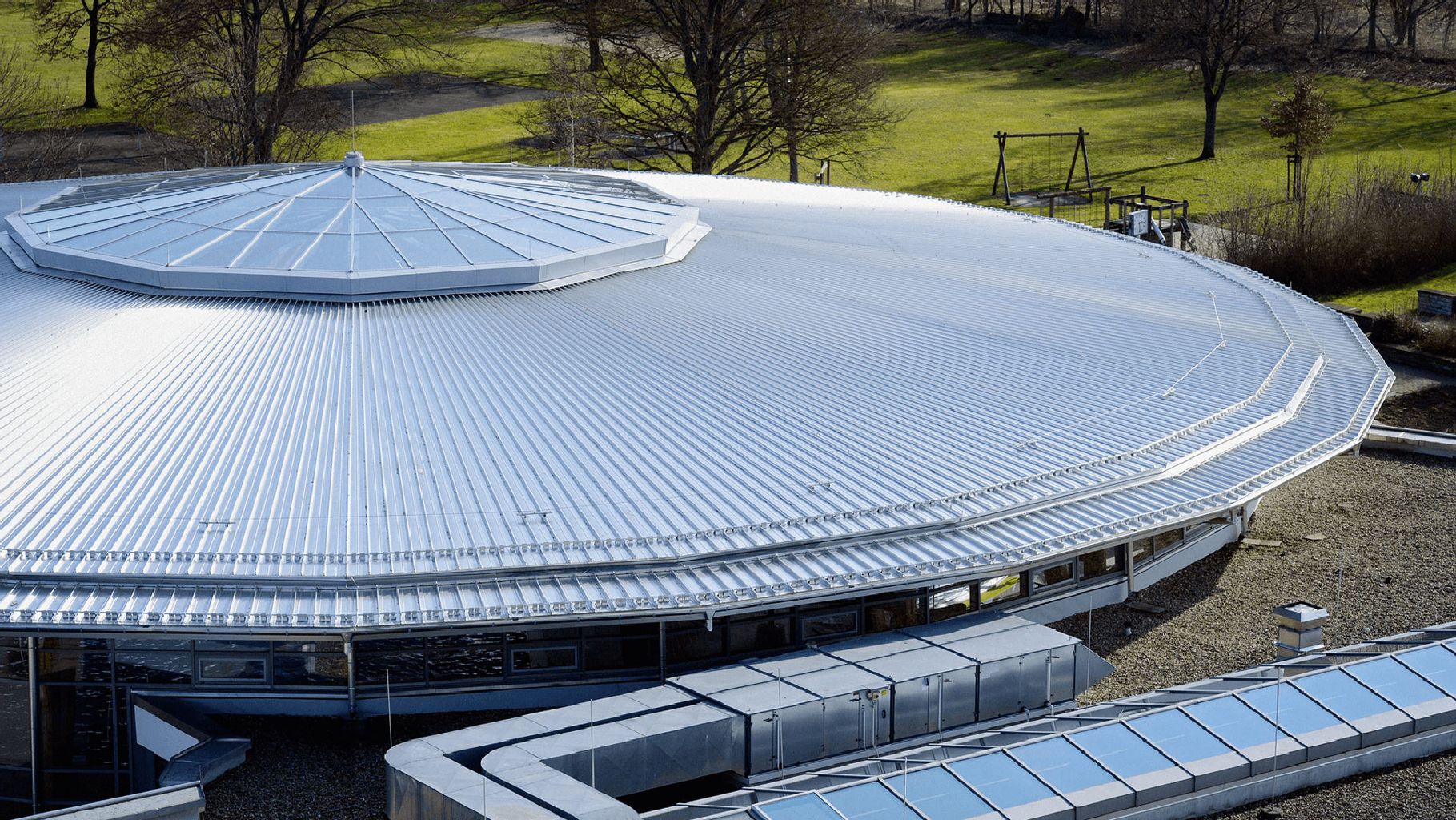

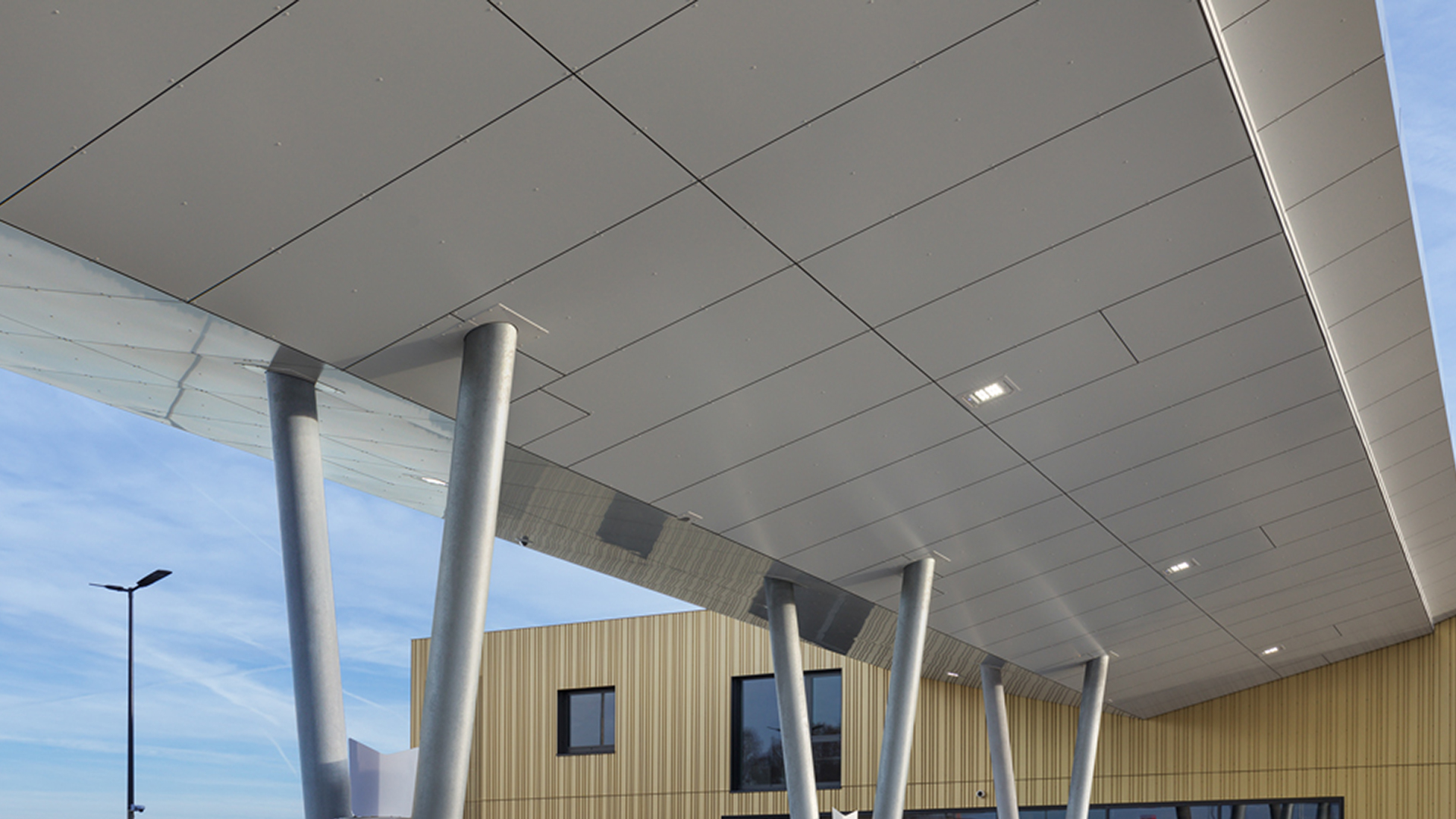

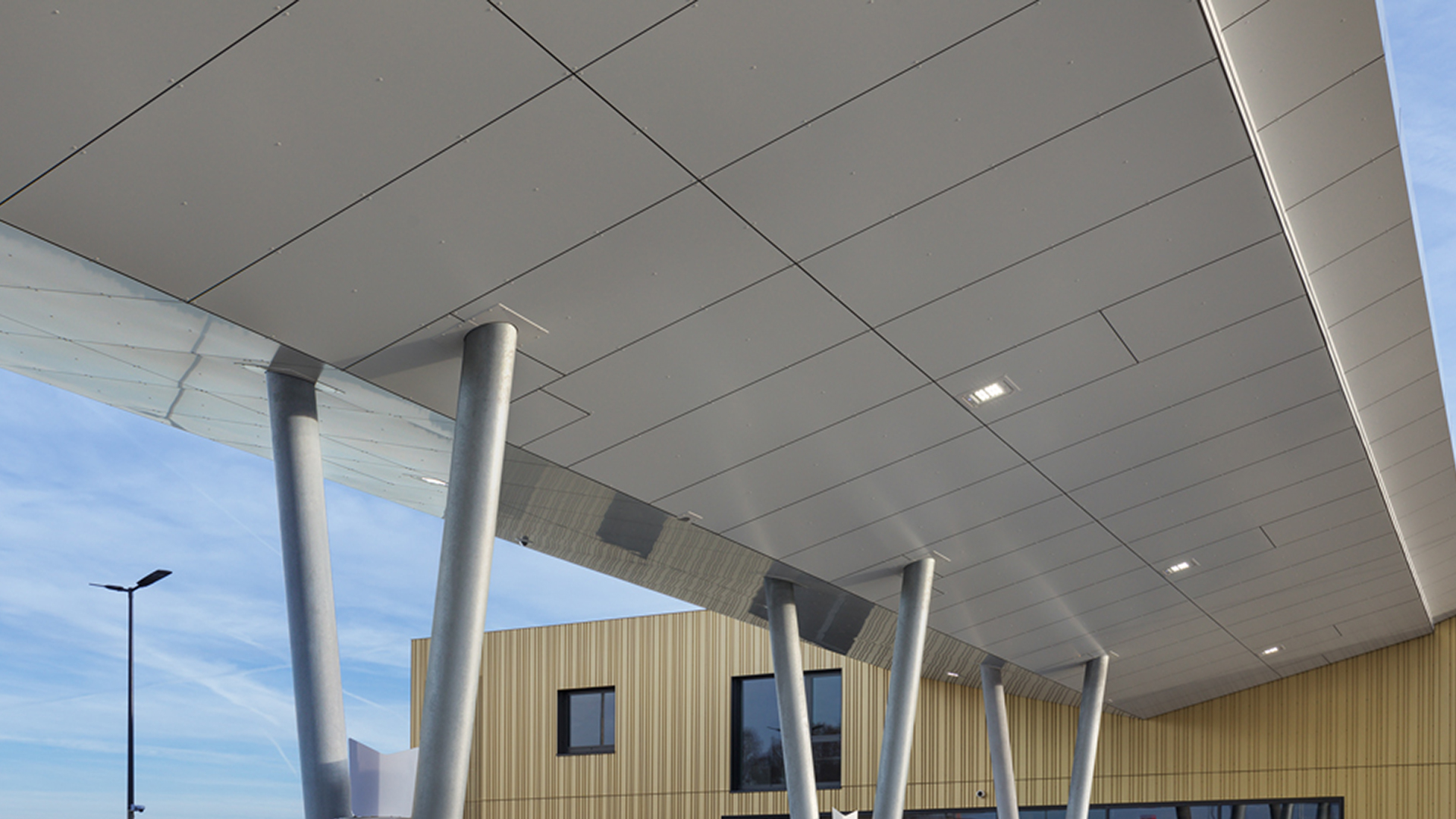

Dach- und Fassadensysteme sind unsere Leidenschaft

BEMO schafft langanhaltende Stabilität, nachhaltige Konstruktionen und individuelle Bauwerke. Die Besonderheit unserer Systeme für Dach und Fassade liegt in der Flexibilität für projektbezogene Sonderlösungen. Wir lieben was wir tun: Ihr erfahrener Partner in individuellen Projekten zu sein. Sie werden das schätzen.

Unternehmen

Über BEMO

Projektpartner auf Augenhöhe

Wenn Partnerschaft auf BEMO-Projekterfahrung trifft,

zeigen sich Vielseitigkeit und Individualität

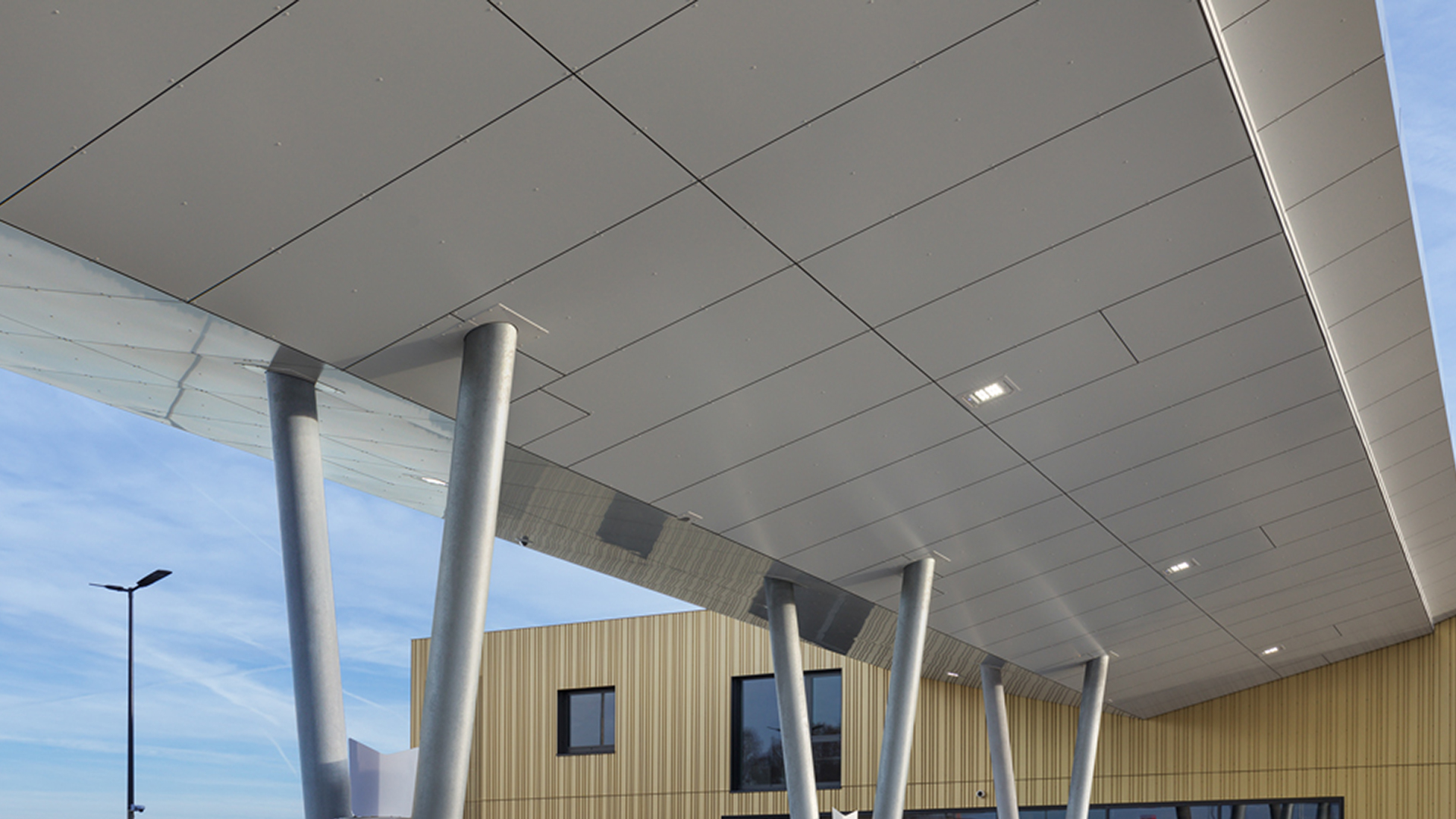

Planung. Statik. Lieferung. Für Systeme und Sonderlösungen. Alles aus einer Hand, wenn es um metallische Gebäudehüllen geht. So verstehen wir unsere Aufgabe. Dabei ist unser Anspruch: Ihr Projektpartner auf Augenhöhe zu sein. Wir unterstützen Bauherren, Generalunternehmer, Architekten und Ingenieure in allen Projektphasen. Unser eigenes Planungsbüro ist eines der größten Fachplanungsbüros für metallische Gebäudehüllen in der Branche und hoch spezialisiert in der 3D-Planung. In enger Zusammenarbeit mit unseren Fach-Montagepartnern begleiten wir Projekte bis Realisierung vor Ort.

Heute schon an Morgen denken

Wir sind nachhaltig.

Dies sind nur einige Merkmale moderner, nachhaltiger Gebäude. Die BEMO Dach- und Fassaden-Systeme erfüllen diese in besonderer Weise. Sowohl das Dach als auch die Fassade aus Metall garantieren in Kombination mit unseren innovativen Systemen ein hohes Maß an Standfestigkeit und Nachhaltigkeit.