BEMO-PRIMO clip façade: The flexible façade construction

For interchangeable and variable use

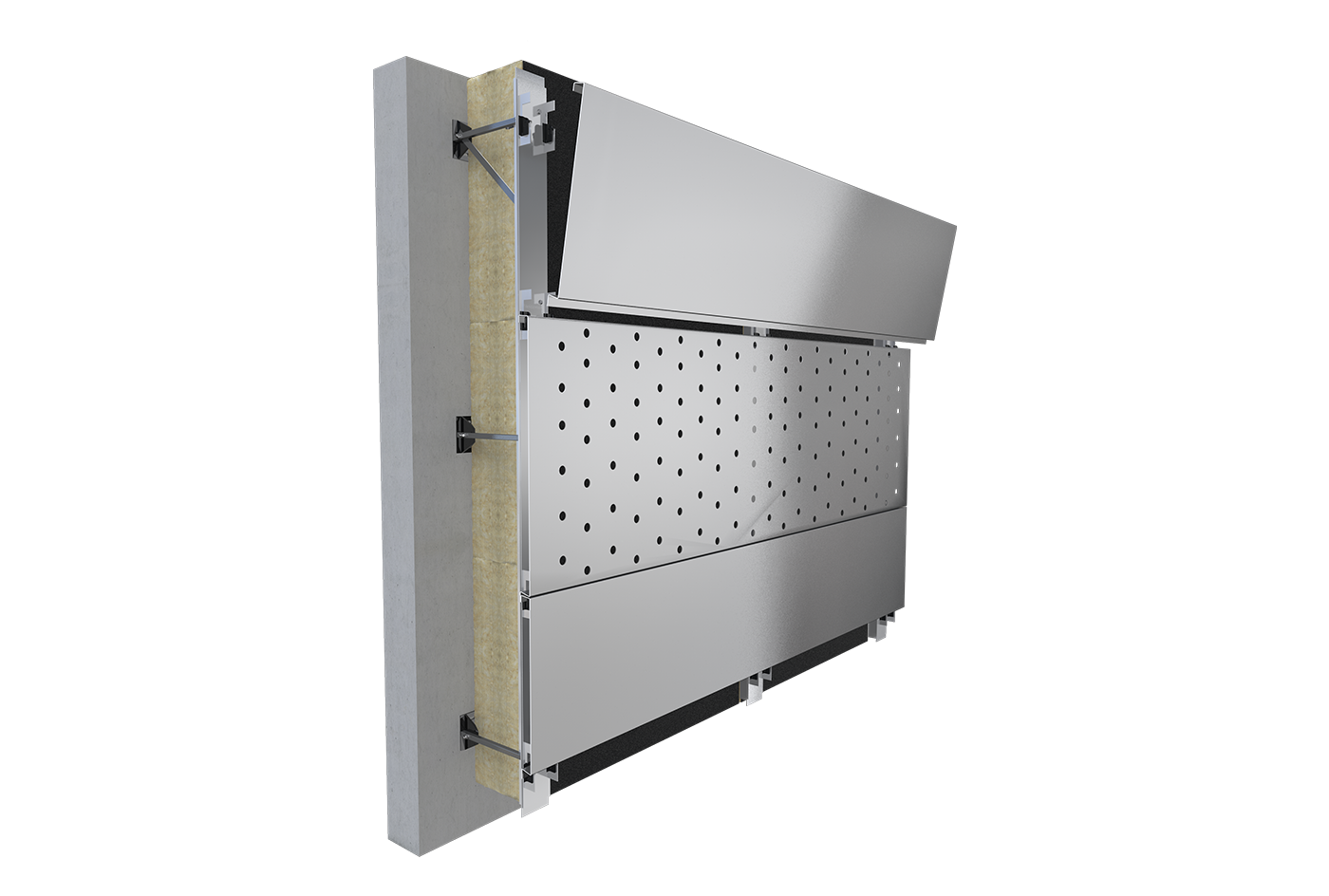

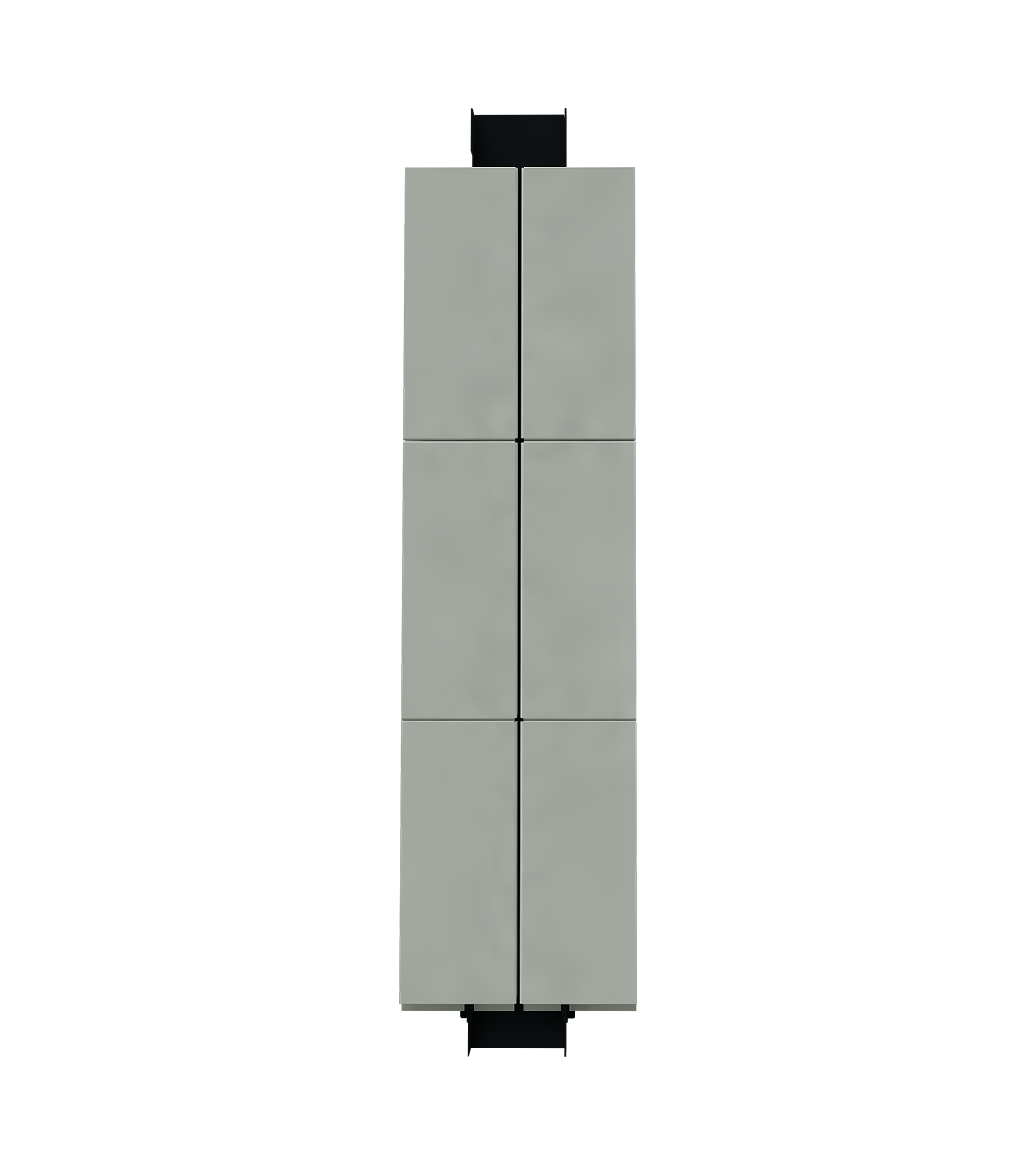

The PRIMO clip façade is a solution made of steel and as such the economically optimal façade construction for corporate buildings. With BEMO-PRIMO, grid dimensions between 200 mm and 800 mm can be freely designed. With the PRIMO substructure, the façade can be mounted on any substrate: concrete, timber, cassettes or mixed.

Thanks to an innovative fixed point technology, the panels of the PRIMO façade construction can be removed and replaced even after installation. This is a great advantage in buildings that quickly show damage. The linear expansion occurs without constraint, permanently and completely stress-free. This guarantees a high-quality façade appearance.

The final assembly of the façade is performed by clipping the panels and is therefore accomplished quickly and economically. The high-quality appearance of the PRIMO clipped façade is further enhanced by corner and reveal structures. On top of that, the panel widths and lengths are freely selectable, and the PRIMO rails can be used in variable depths. This allows connections to the façade penetrations to be an exact fit.

-

Economical optimal façade construction

made of steel -

Panels can also be replaced at a later date

thanks to the innovative fixed point technology -

Quick, easy and economical installation

by clipping the panels -

Can be mounted on any surface

with the PRIMO substructure

The basis for façade constructions with BEMO-PRIMO

Substructure for tolerance compensation and against thermal bridges

The substructure is the connection between the load-bearing wall and the façade cladding. By anchoring the façade construction in the outer wall it transfers the weight of the façade cladding to the structure of the building. BEMO offers innovative substructure systems for rainscreen façades and other façade systems to compensate tolerances and to secure an installation free of thermal bridges.

We work out individually which substructure suits which requirements and which façade construction – in close cooperation with you, taking all the circumstances into account.

Inspiration

Central plant Engeser

Double-deck three-field sports hall FFM

Company Building Flachstahl Werl

Corporate Building Leonhard Moll Betonwerke Biebesheim

360° Service

Synergetic partnership in all project phases.

BEMO has its own planning office equipped with the most modern, partly specially developed 3D planning technology, with which our system-experienced technicians and engineers accompany your projects professionally from the start. From the initial consultation, the specialists at BEMO look after your project and accompany the implementation of the desired design, the choice of materials and the design. This also includes the first technical details and static preliminary measurements and finally the complete implementation and workshop planning.

In order to optimize your project economically, we make transparent cost estimates as well as variant calculations and initiate technical optimizations. On top of that, 3D measurements as the basis for our well thought-out and easy-to-assemble systems, as well as the implementation in 3D planning, guarantee efficient implementation. All of this falls under our understanding of a comprehensive partnership with BEMO.