Digesters operate very efficiently when the internal temperature is about 36 degrees. The thermal envelope must function correctly and reliably to maintain this temperature permanently and without large fluctuations. This includes a tight building envelope, correct connections, functioning plant technology and dry thermal insulation.

Even slight moisture penetration of the thermal insulation, for example due to leakage, leads to a considerable loss of insulation and therefore to significantly increased heating costs. This can be avoided by renovating the digester. The thickness of the thermal should be at least 250 mm in order to provide good thermal protection and enable efficient operation.

Ensure thermal insulation of the digester tank through digester renovation

Only a few decades ago, not much emphasis was placed on thermal insulation in the construction of digester towers. In reality, the existing digesters only have 6-8 cm of insulation. With such poor insulation, the heat losses are enormous and the costs for heating the digester are huge.

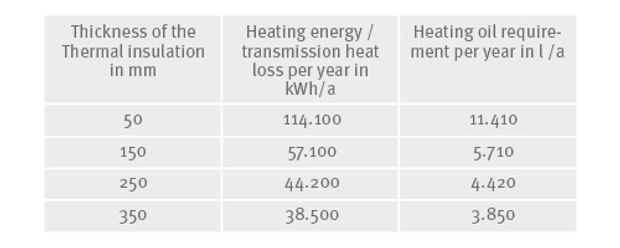

Objects renovated with the BEMO system (for example with a 200 mm insulation layer) show that heating costs can be reduced by up to 50 % through digester renovation, while simultaneously increasing the gas yield by over 30 %. The calculations in the table were developed by respected engineering firm Dress and Sommer show the transmission heat losses and the equivalent amount of heating oil required to heat digesters with different insulation thicknesses. The calculations are based on a substructure free of thermal bridges.

It is evident from the table that insulation of at least 250 mm is required for efficient operation of a digester. This optimal insulation thickness can be reduced by up to 40% with a wall construction free of thermal bridges during digester renovation. Conversely in a construction with metallic thermal bridges, an insulation thickness of up to 350 mm is necessary for the same insulation performance when renovating the digestion tower.

Sustainable digester renovation with recyclable solutions from BEMO

Durable, low-maintenance and recyclable building envelopes. With special solutions for tolerance compensation of the concrete structure and towers of any shape. Optimal building renovation with BEMO.

Why BEMO?

- Planning support and project monitoring

- Sustainable, durable, recyclable materials and systems

- System solutions for every building shape

- Highly resistant special BEMO-FLON coating

Inspiration Special Buildings & Refurbishment

digestion tower Bitburg