3D façade solutions for individual free-form façades

Flexible façade solutions from BEMO make it possible

The freely implementable façade solution: With the 3D façade from BEMO, building design is almost unlimited. It is the adaptable concept that creates unique building envelopes. The 3D façade from BEMO makes free-form façades possible. The well-engineered façade system offers a variety of functional and visual designs that give space to individual building ideas.

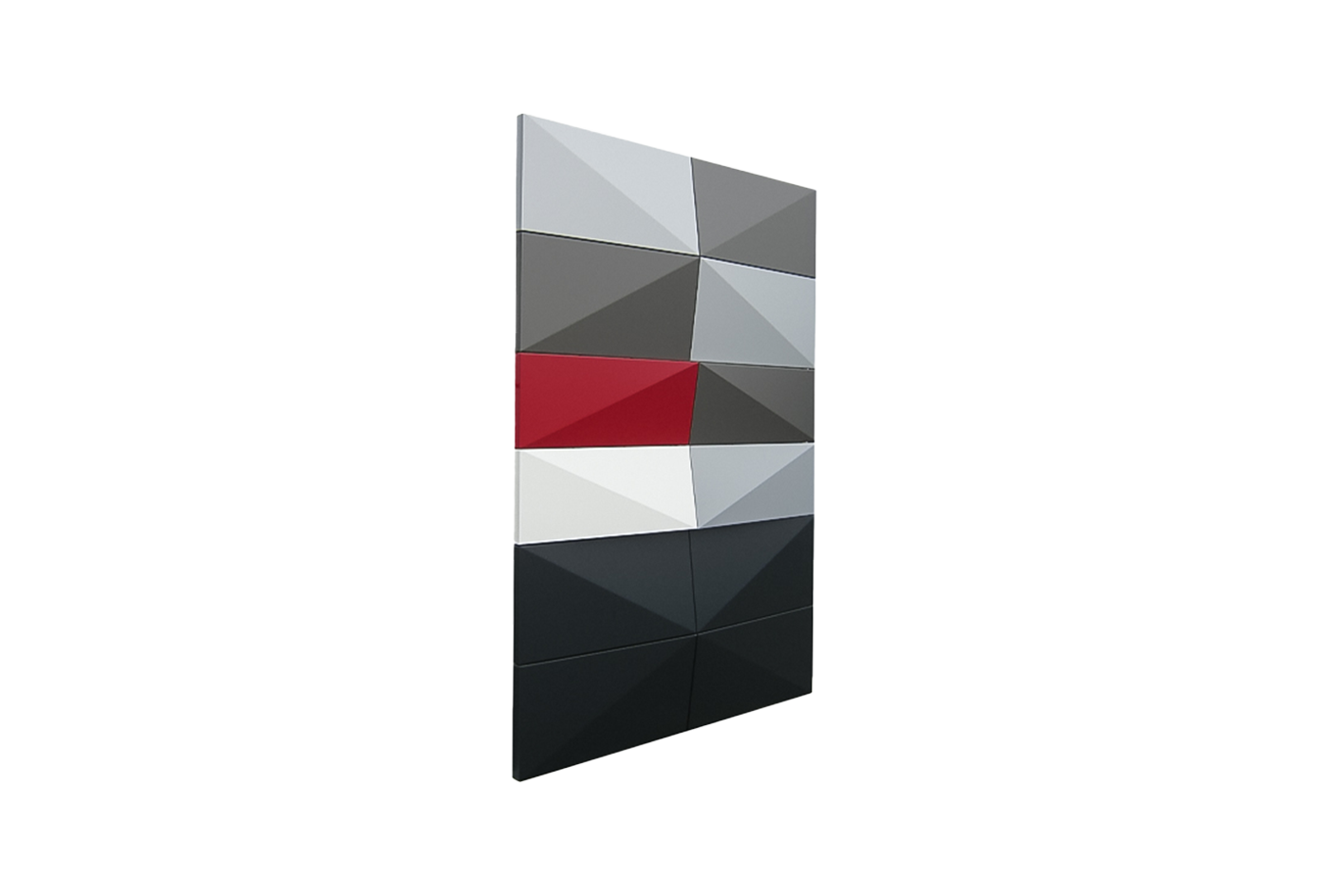

3D façade cladding

New design possibilities with 3D façade cassettes

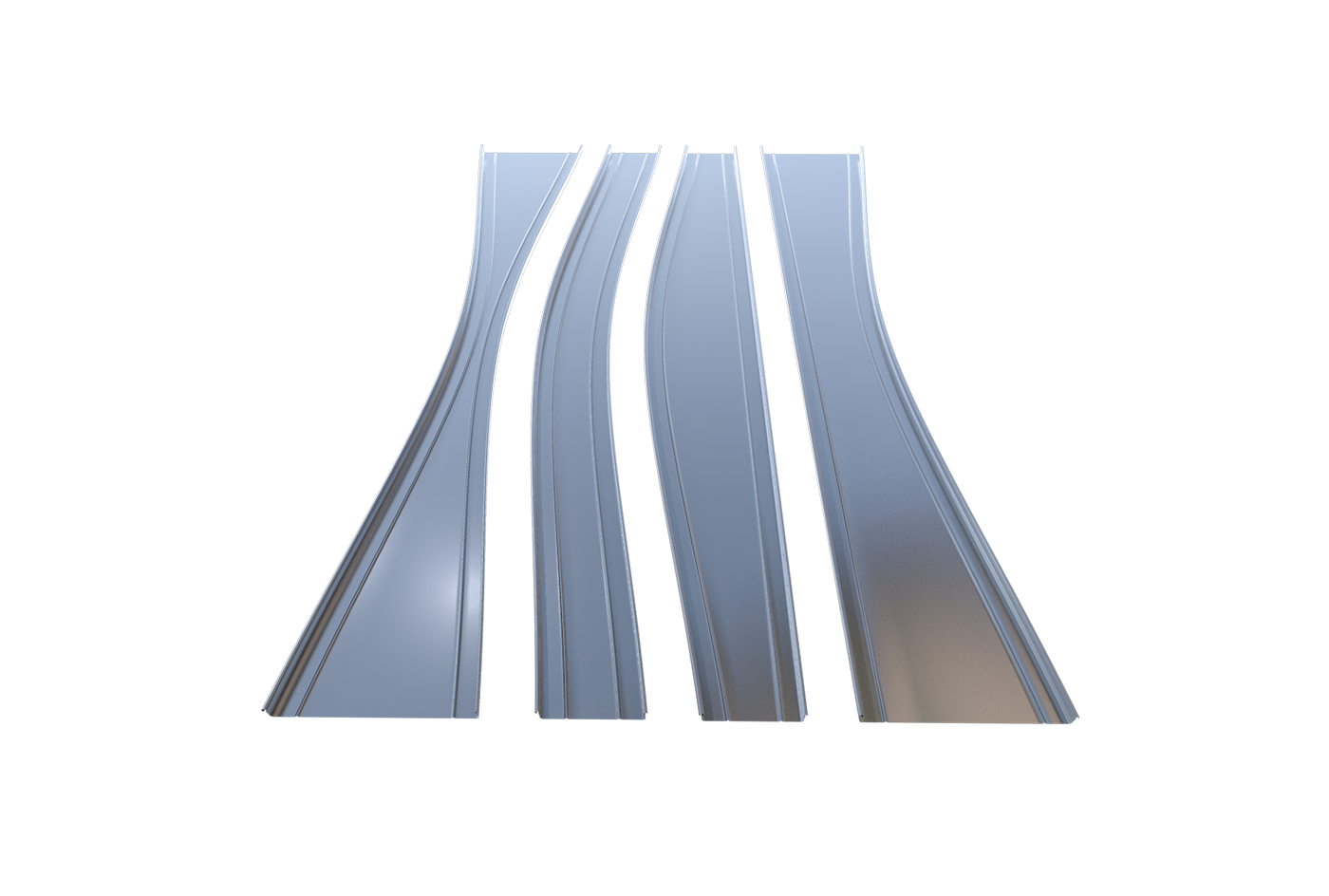

BEMO-MONRO® is the system for a flexible standing seam covering for 3D façades

More adaptability for free-form buildings with special profiles

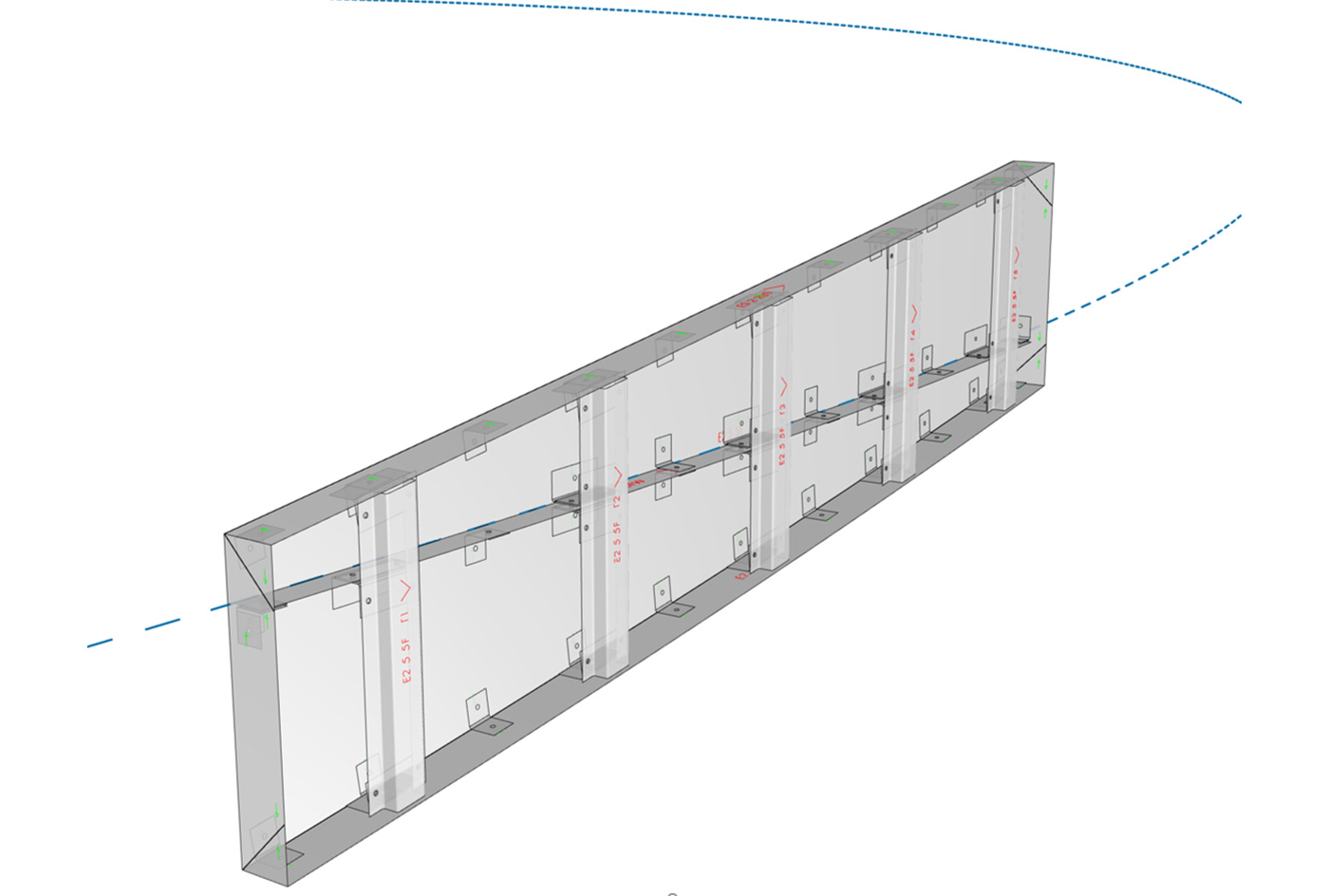

Usually, the MONRO® system is combined with a three-dimensionally adjustable substructure. This allows an easy and efficient correction of unevenness in the supporting structure. BEMO 3D design plans the system ready for installation in the standing seam roofing of the 3D façade.

For larger circular or even for conical buildings, special conical profiles are used. With a minimum width of 100 mm and a maximum covering width of 800 mm, these special profiles make the implementation of almost any requirement possible. For the reason that the standing seam sheets are formed to fit precisely for the 3D façade in a single work step, there is no need for time-consuming trimming during the project.

All special profiles are also offered in curved shapes and in all materials.

Inspiration

Hotel L’EssenCiel

Garagum Hotel & Business Center

Residential Building Glitne in Umeå

Błonie Sports Center

Stadium Lublin

360° Service

Technical support on its best

The implementation of your 3D façade is fully supported by our BEMO planning office. Together we master every challenge and pave the way for your individual project – with system-experienced technicians and engineers. These work with the most modern, partially in-house developed 3D planning technology. Your work includes the initial consultation as well as the implementation of the desired design, the choice of materials and design, as well as the first technical details and static preliminary measurements. Our team accompanies you through the complete implementation and workshop planning.

With our cost estimates, technical optimizations, or variant calculations, we help you to optimize your ideas economically. 3D measurements serve as the basis for our well thought-out and easy-to-assemble systems. The implementation takes place in the same way with 3D planning. This is what a comprehensive partnership with BEMO looks like for us.